Introduction

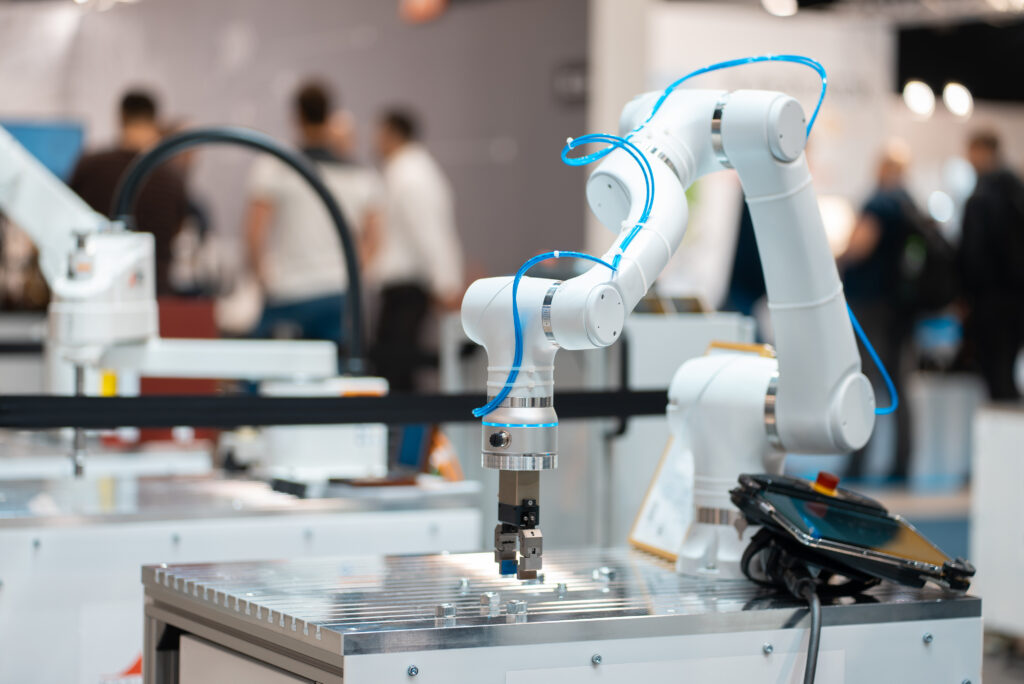

Automated manufacturing has transformed industries worldwide, reshaping production processes, enhancing efficiency, and driving innovation. This article explores the significant impact of automated manufacturing on various sectors and its role in shaping the future of business.

Outline

- Introduction

- Background

- Understanding automated manufacturing

- Advantages and benefits

- Case studies: Industry applications

- Future perspectives

- Conclusion

- FAQs

Background

Automated manufacturing, controlled by innovations like automated manufacturing, man-made reasoning, and high-level automated manufacturing has changed conventional assembling processes. This segment gives an outline of the advancement of automated manufacturing production and its far and wide reception across businesses.

Understanding Automated Manufacturing

Automated manufacturing assembling offers various benefits, including expanded efficiency, work quality, improved well-being, and diminished costs. This segment investigates the critical advantages that automated manufacturing fabricating brings to enterprises and organizations, everything being equal.

Advantages and Benefits

While the advantages of automated manufacturing production are significant, execution can pose difficulties such as high forthright expenses, automated manufacturing, and labor force transformation. This segment talks about the normal difficulties faced during the execution of automated manufacturing production arrangements and systems to address them.

Case Studies: Industry Applications

This section uses real-world case studies to illustrate the diverse applications of automated manufacturing across industries such as automotive, electronics, aerospace, healthcare, and consumer goods. These examples demonstrate how automated manufacturing has transformed production processes and enhanced competitiveness.

Future Perspectives

Looking forward, the fate of automated manufacturing fabricating holds enormous potential for additional development and progression. This part investigates arising patterns like cooperative advanced mechanics, digitalization, added substance producing, and supportable automated manufacturing rehearses, and their suggestions for ventures.

Conclusion

In conclusion, automated manufacturing has emerged as a game changer for industries, enabling them to achieve higher levels of efficiency, flexibility, and competitiveness. By embracing automation technologies, organizations can unlock new opportunities for growth and innovation.

FAQs

1. What is automated manufacturing?

Automated manufacturing and fabricating alludes to the utilization of trend-setting innovations in automated creation processes, diminishing the requirement for human intervention and improving productivity.

2. What are the key benefits of automated manufacturing?

Automated manufacturing offers advantages like expanded efficiency, work on quality, upgraded security, diminished costs, and more noteworthy adaptability.

3. What are some common challenges in implementing automated manufacturing solutions?

Difficulties might include high introductory venture costs, automated manufacturing, labor force preparation, coordination issues, and network protection chances.

4. How is automated manufacturing applied in different industries?

Automated manufacturing is applied across various ventures, including auto, contraptions, flying, clinical benefits, and client stock, to streamline creation processes and further foster earnestness.

5. What are the emerging patterns in automated manufacturing?

Emerging examples integrate helpful high-level mechanics, digitalization, added substance creation (3D printing), attainable automated production practices, and the coordination of man-made cognizance and artificial intelligence.