Applications

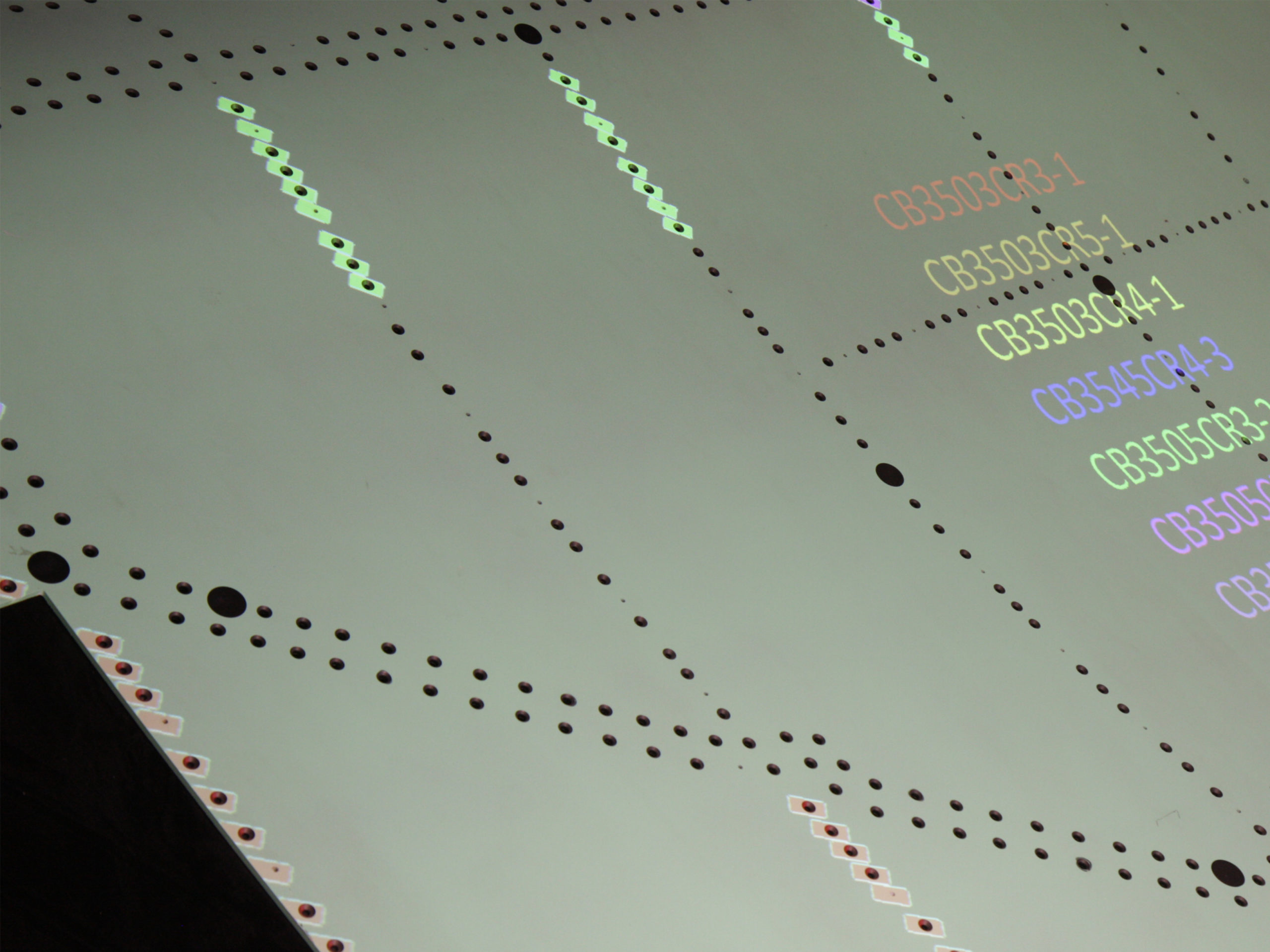

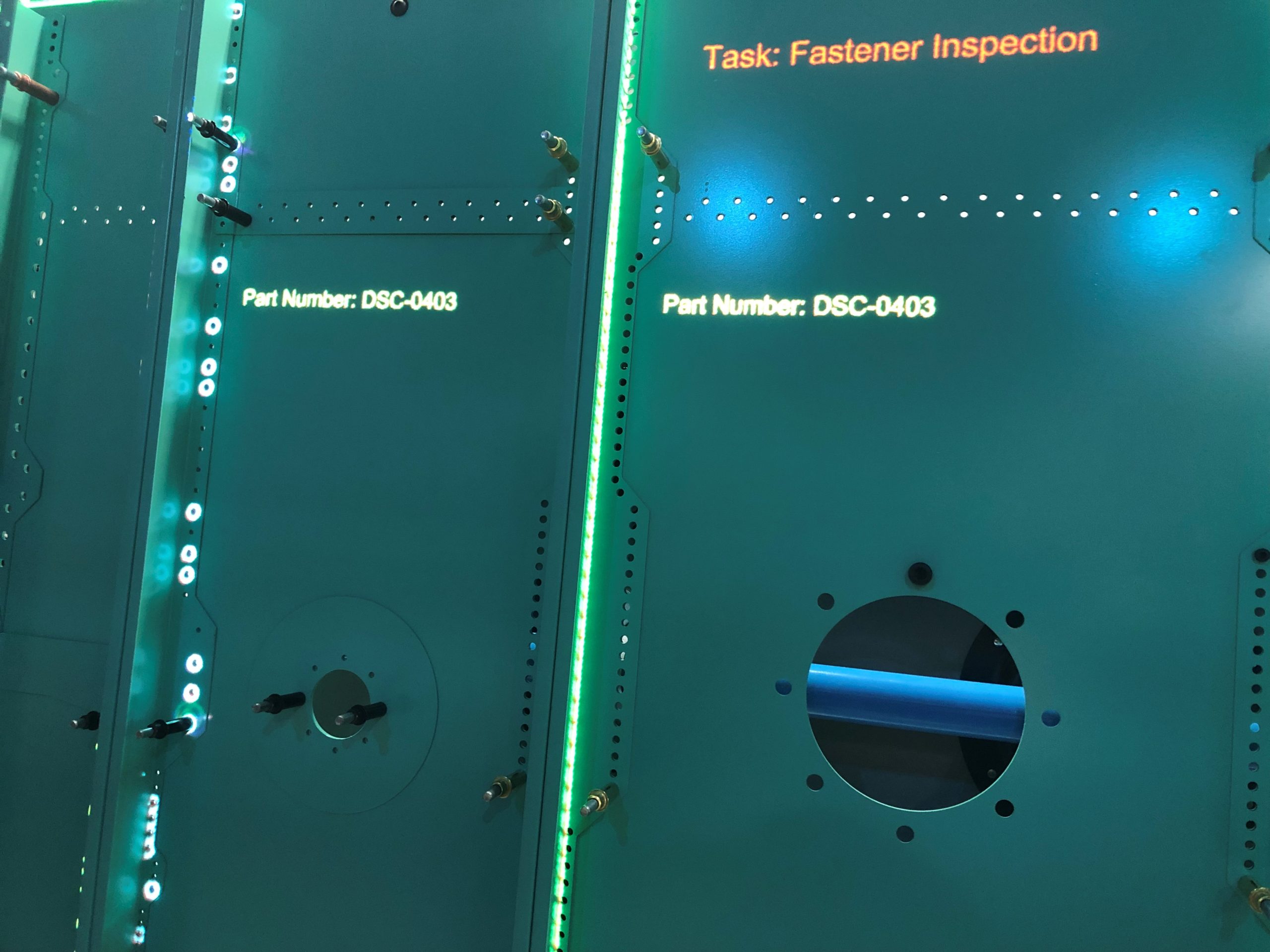

Mechanical assembly fastener installation.

ProjectionWorks

Mixed Reality For Manufacturing

ProjectionWorks™ is a family of products that are used to provide three-dimensional instructions to various manufacturing processes.

US Airforce Approved

3D Projection Mapping Solution

ProjectionWorks™ patented software was first developed by Delta Sigma Company in 2010 in collaboration with the United States Airforce Research Program. The goal was to provide a low-cost solution for delivering clear and specific optically projected work instructions onto an aircraft.

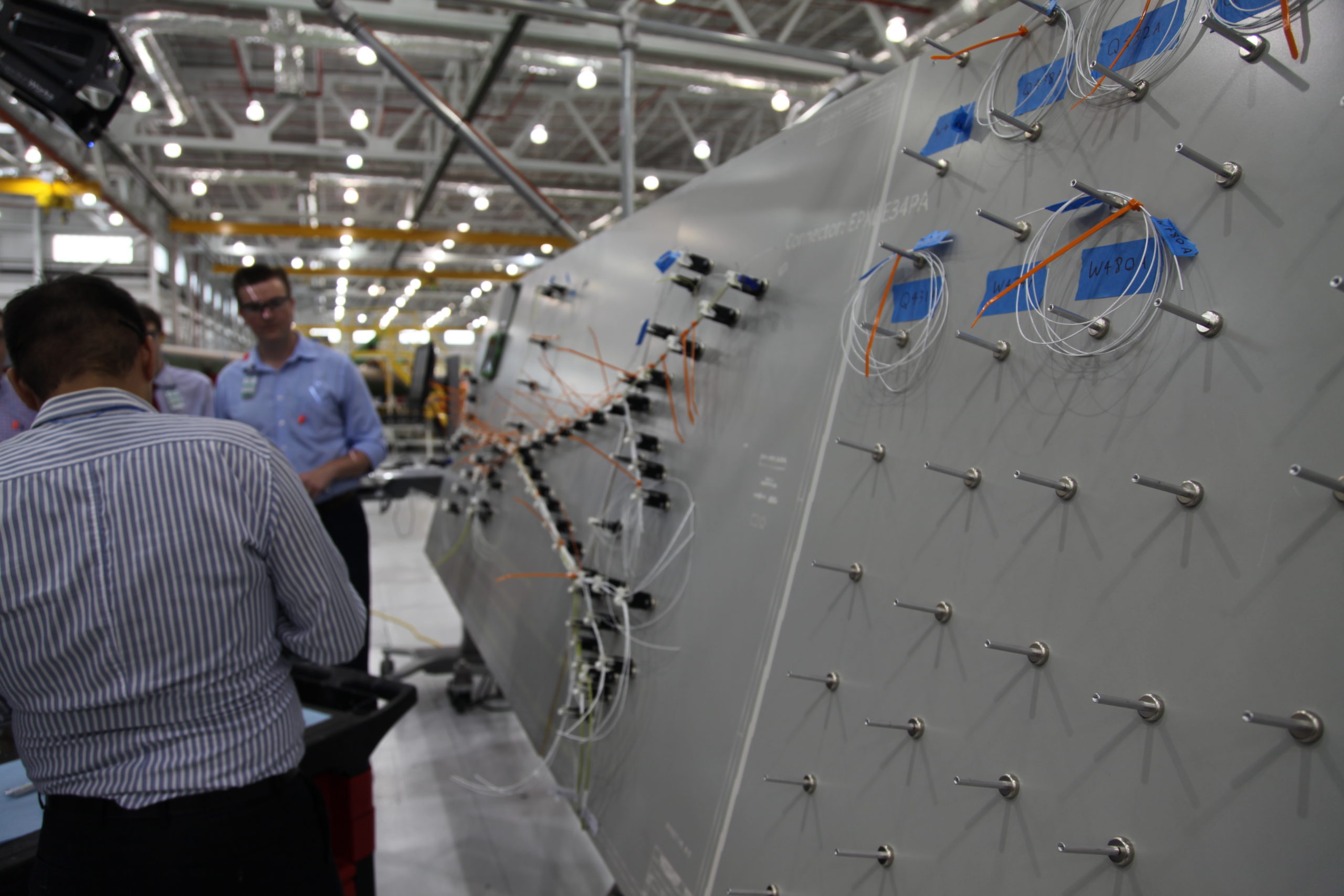

The result was a hardware/software solution that includes everything needed to display a significant amount of knowledge to assembly technicians for a large number of different types of assembly tasks. This knowledge is displayed at the exact place that it is needed, in an order that has been predetermined to be the optimal build-sequence. This type of instruction set is extremely beneficial to manufacturers of aircraft, rockets, satellites, missiles, bombs, ships, submarines, boats, heavy equipment, buses, or other types of large, relatively low production but complex, high-value systems.

The Air Force’s “Customer/Supplier Interoperability during Collaborative Design (CSI)” and OSD/DMS&T’s “3D Technical Data Package & Certification” projects have greatly reduced time to mission for weapon systems by enabling the seamless transfer of product data throughout the system’s lifecycle – getting the right data to the right people in a format that they can use. Through side-by-side comparisons with current best practices, these two programs generated projected cost savings of ~$50M per year when fully adopted by a single, large defense supply chain. Both of these programs significantly benefitted from OSD Defense-wide Manufacturing Science & Technology funding.

U.S. Department of Defense .

Manufacturing technology Program

2012 Defense Manufacturing Technology Award

The 2012 Defense Manufacturing Technology (ManTech) Achievement Award recognizes and honors the team whose project demonstrated outstanding technical accomplishments in achieving the Department of Defense ManTech Program vision to “realize a responsive world-class manufacturing capability to affordably meet war fighters needs throughout the defense system life cycle.” The annual award is sponsored by the Joint Defense Manufacturing Technology Panel (JDMTP), and was presented on Nov. 27, 2012, at the Defense Manufacturing Conference in Orlando.

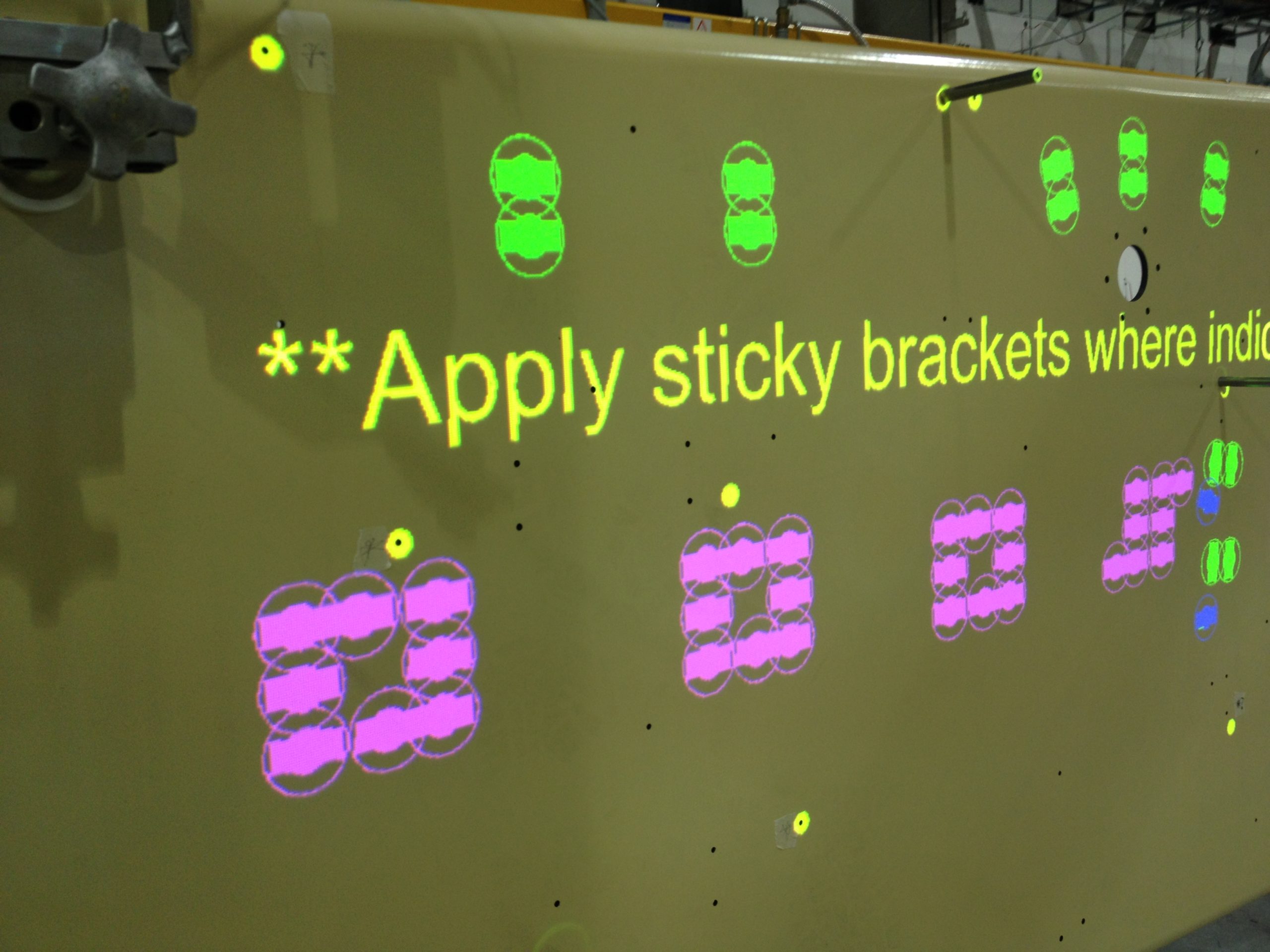

Masking a projected paint scheme.

What is

Mixed Reality?

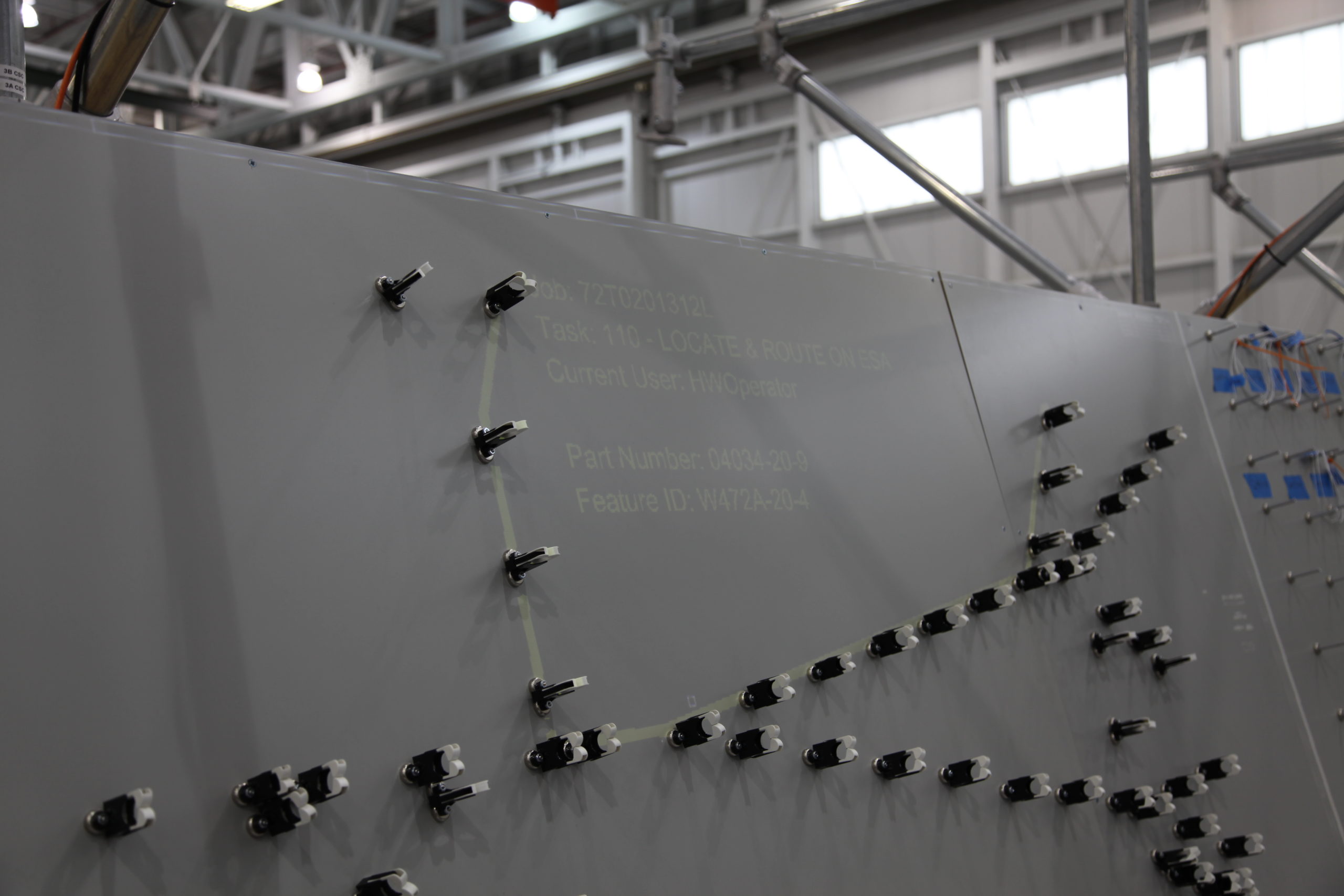

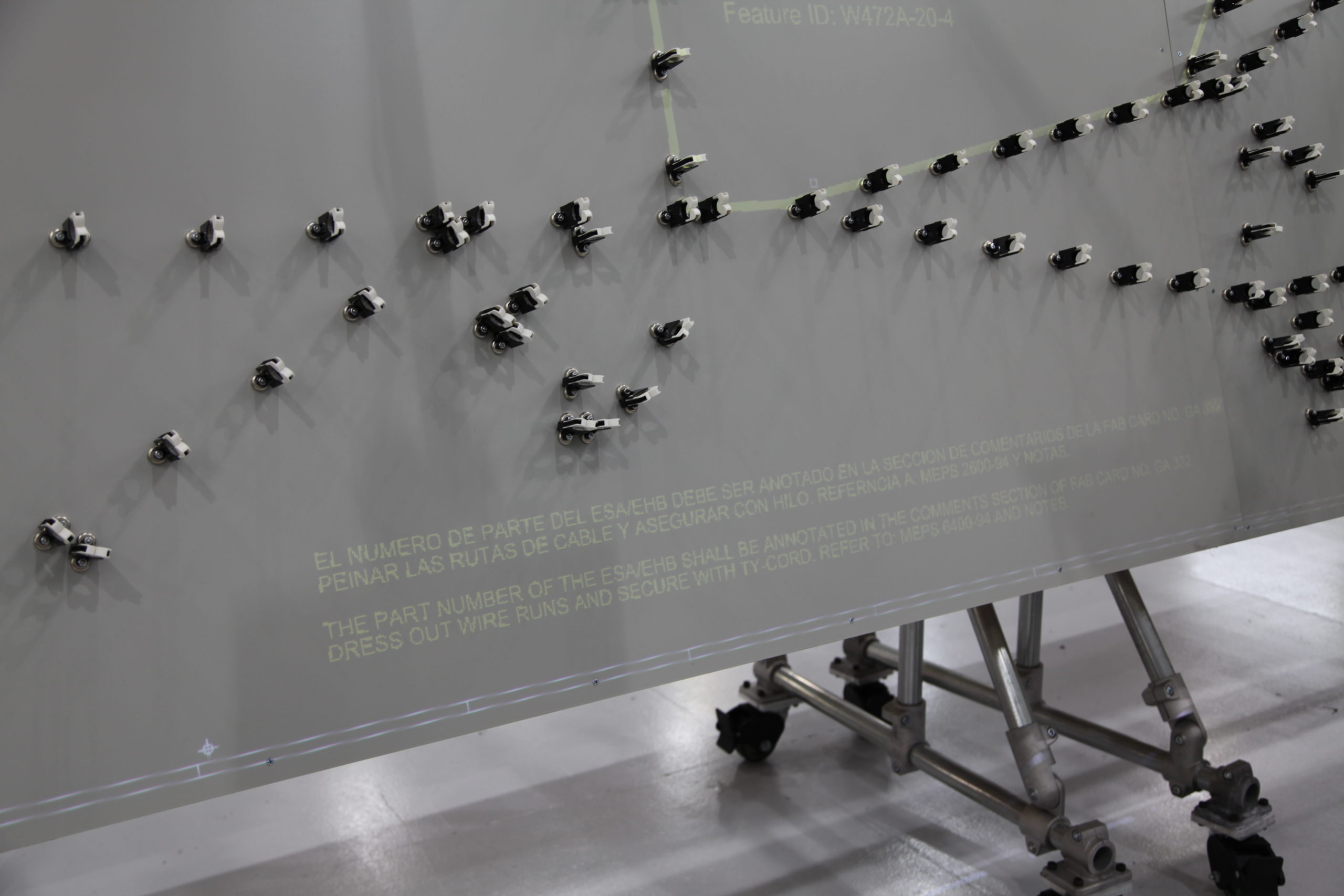

We use Mixed Reality to simplify complex tasks. This is achieved through an integrated system that imports and creates 3D geometry to project simple yet concise work instructions onto any contoured surface.

Unlike Augmented Reality which is a live video stream from a camera that is being augmented by

Virtual Reality components added into the video, Mixed Reality goes one step further by enabling

the user to view a real physical object and see Virtual Reality superimposed on it.

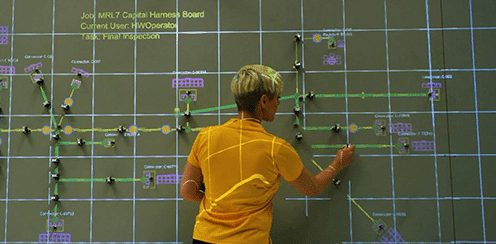

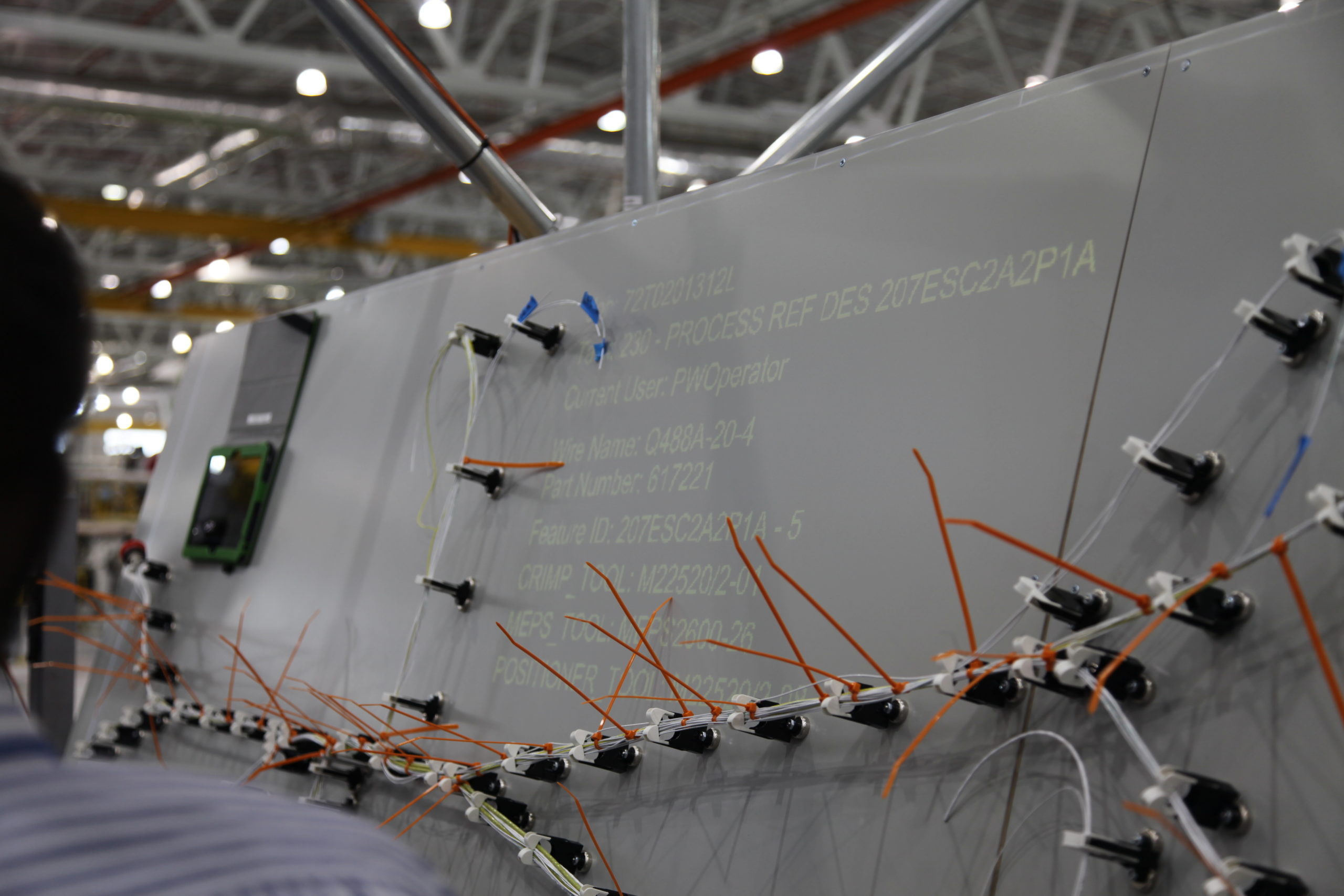

Projected Work Instructions for Wire Harness Assembly.