Introduction

Welcome to the domain of precision design. Precision machining strategies are the foundation of current assembly, empowering the making of unpredictable parts with unrivaled accuracy. In this article, we discuss mastering precision by exploring Precision machining techniques

Outline

- Introduction

- Background

- Understanding Precision Machining Techniques

- Key Techniques and Processes

- Applications Across Industries

- Advantages and Challenges

- Conclusion

- FAQs

Background

Understanding Precision Machining Techniques

Precision machining methods include a scope of processes that include the expulsion of material from a workpiece to accomplish exact aspects, tight resistances, and excellent surface completions. These strategies require advanced apparatus, gifted administrators, and fastidious scrupulousness.

Key Techniques and Processes

Investigate the fundamental strategies and processes basic to machining:

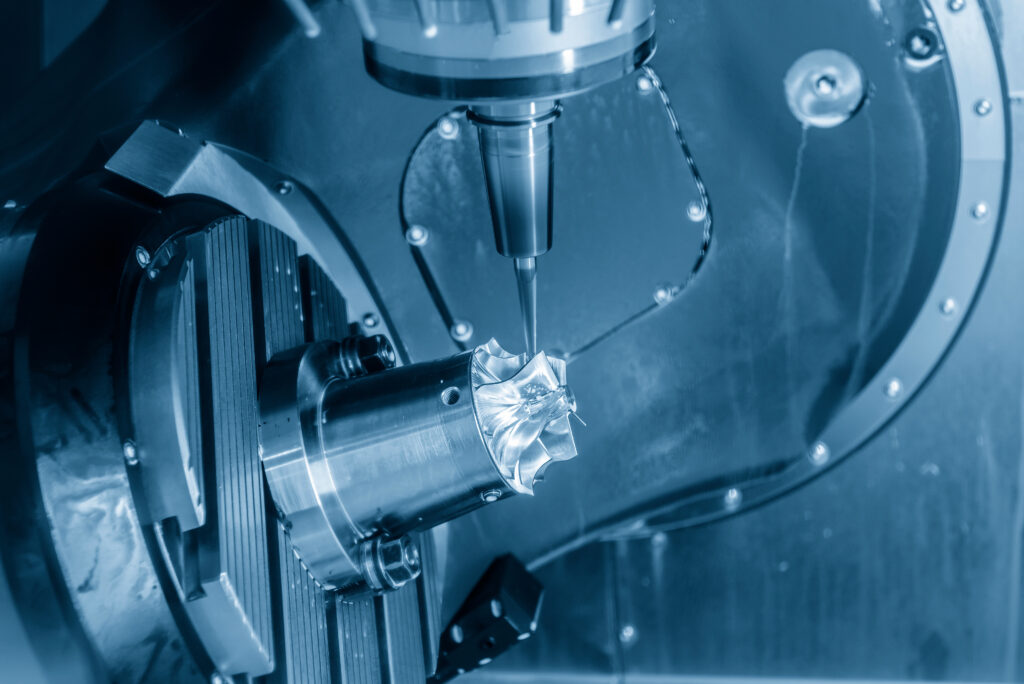

- CNC Machining: Computer Numerical Control (CNC) machining utilizes PC controlled hardware to definitively control the development of cutting apparatuses, taking into account the exact creation of intricate parts.

- Turning and Milling: Turning and processing tasks include the pivot of a work piece against a slicing device to shape and frame it into the ideal calculation, accomplishing exact aspects and surface completions.

- Grinding and Finishing: The crushing and completing processes refine the surface completion and layered precision of machined parts, guaranteeing tight resistance and top notch wraps.

- EDM Machining: Electrical Discharge Machining (EDM) utilizes electrical sparkles to dissolve material from the work piece , empowering the development of mind boggling shapes and highlights with high accuracy.

Applications Across Industries

Find the assorted utilizations of precision machining procedures across different ventures, including:

- Aerospace: Precision machined parts are fundamental for airplane motors, underlying parts, and basic aviation frameworks, where unwavering quality, execution, and security are vital.

- Medical: Precision machining procedures are utilized to fabricate clinical gadgets, inserts, and careful instruments with precision, guaranteeing similarity, usefulness, and security.

- Automotive: Precision machined parts are indispensable to car fabricating for motors, transmissions, and case parts, where strength, execution, and effectiveness are vital.

- Electronics: Precision machining assumes an urgent role in gadgets fabrication for creating parts like connectors, lodgings, and intensity sinks with tight tolerances and many-sided highlights.

Advantages and Challenges

While Precision machining Strategies offer various benefits, they additionally present difficulties, for example,

- High Precision and Accuracy: Precision machining procedures enable the development of parts with tight tolerances. They also facilitate the creation of complex geometries and excellent surface finishes. These processes meet the demanding requirements of various industries.

- Versatility and Flexibility: The machining process can accommodate a great many materials, sizes, and shapes, offering adaptability in part production.

- Cost and Complexity: Carrying out and maintaining precision machining equipment and processes requires investment in specialized equipment. Skilled labor and quality control measures are essential. This presents challenges in terms of cost-effectiveness and adaptability.

Conclusion

In conclusion, exploring precision machining techniques is fundamental to achieving excellence in modern manufacturing. Industries continue to push the limits of precision engineering. Precision machining methods remain at the forefront, driving innovation, quality, and reliability in part production.

FAQs

1. What are precision machining techniques?

Precision machining procedures incorporate a range of processes. These processes involve the precise removal of material from a workpiece. The goal is to achieve tight tolerances, precise aspects, and high-quality surface finishes.

2. What industries rely on precision machining techniques?

Ventures like aviation, medical, automotive, and electronics rely heavily on precision machining methods. These methods are essential for the production of critical parts with precision.

3. What are the benefits of precision machining techniques?

Precision machining strategies offer advantages like high precision and accuracy. They also provide flexibility and versatility in manufacturing. This enables the production of complex parts with tight tolerances and high-quality finishes.