Introduction

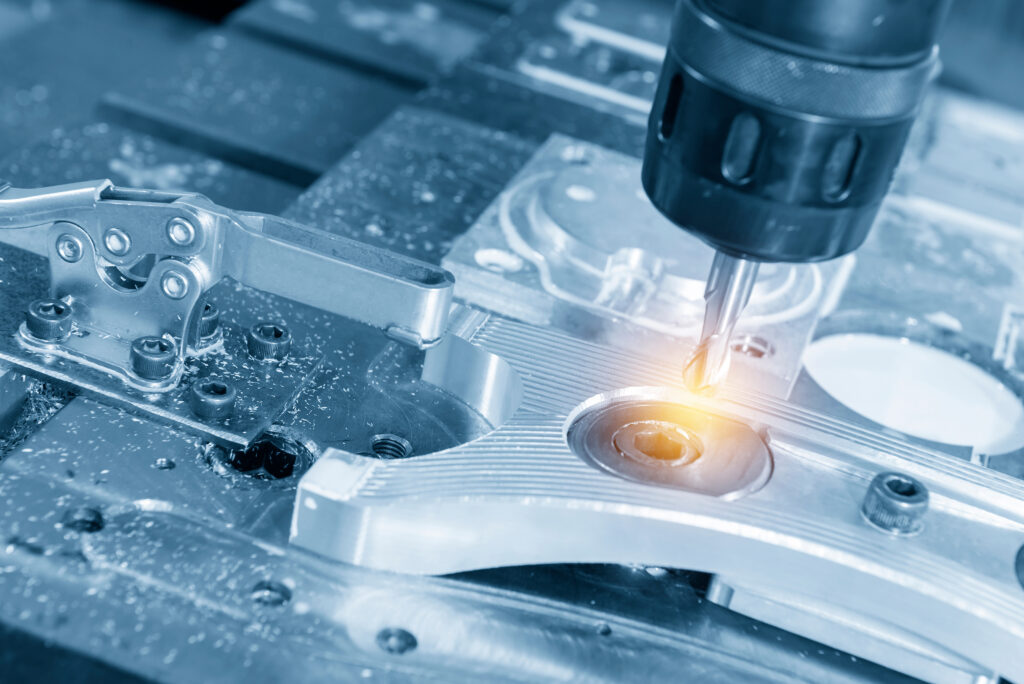

Welcome to the universe of precision design- Precision machining is a refined process that lies at the core of present-day production, opening up the potential for making unpredictable parts with unrivaled exactness and accuracy. In this article, we dive into the complexities of precision machining, unlocking the secrets of precision machining, and displaying its importance in forming ventures.

Outline

- Introduction

- Background

- Understanding Precision Machining

- Key Techniques and Processes

- Applications Across Industries

- Advantages and Challenges

- Conclusion

- FAQs

Background

Understanding Precision Machining

Precision machining is an assembling process that includes the expulsion of material from a workpiece to accomplish exact aspects, tight tolerances, and top-notch surface finishes. It requires advanced apparatus, talented administrators, and fastidious scrupulousness to guarantee exactness and accuracy.

Key Techniques and Processes

- CNC Machining: Computer Numerical Control (CNC) machining uses PC controlled hardware to unequivocally control the development of cutting apparatuses, taking into account the exact creation of perplexing parts.

- Turning and Milling: Turning and processing tasks include the revolution of a work piece against a slicing device to shape and frame it into the ideal calculation, accomplishing exact aspects and surface completions.

- Grinding and Finishing: The crushing and completing processes refine the surface completion and layered precision of machined parts, guaranteeing tight tolerances and top notch wraps.

- EDM Machining: Electrical Discharge Machining (EDM) utilizes electrical sparkles to disintegrate material from the workpiece, empowering the creation of perplexing shapes and elements with high accuracy.

Applications Across Industries

Find the different uses of precision machining across different ventures, including:

- Aerospace: Precision machined parts are essential for airplane engines. They are also crucial for primary components and aviation systems. Reliability, performance, and safety are fundamental in these applications.

- Medical: Precision machining is indispensable for assembling clinical gadgets, inserts, and careful instruments with precision, guaranteeing similarity, usefulness, and wellbeing.

- Automotive: Precision machined parts are vital to car production. They are used for motors, transmissions, and suspension parts. Solidity, performance, and efficiency are critical in these components.

- Electronics: Precision machining assumes a pivotal role in gadget fabrication. It delivers parts like connectors, housings, and heat sinks. These are crafted with tight tolerances and intricate features.

Advantages and Challenges

While Precision Machining offers various benefits, it additionally presents difficulties, for example,

- High Precision and Accuracy: Precision machining empowers the development of parts with tight tolerances, complex calculations, and great surface finishes.

- Versatility and Flexibility: The precision machining process can accommodate many materials, sizes, and shapes, offering adaptability in part production.

- Cost and Complexity: Executing and keeping up with precision machining hardware and processes requires investment in specific apparatus. Skilled labor and quality control measures are essential. This presents challenges in terms of cost-effectiveness and versatility.

Conclusion

All in all, by unlocking the secrets of precision machining, we epitomize craftsmanship and precision in modern fabrication. Businesses continuously demand higher levels of exactness and quality. Precision machining remains at the cutting edge, opening additional opportunities and pushing the limits of what is reachable.

FAQs

1. What is precision machining?

Precision machining is an assembling process that includes the exact expulsion of material from a workpiece to achieve excellent surface finishes.

2. What industries rely on precision machining?

Businesses like aviation, clinical, auto, and hardware depend intensely on precision machining for the creation of basic parts.

3. What are the benefits of precision machining?

Precision machining offers advantages like high precision and exactness, flexibility, and adaptability in assembly, empowering the creation of perplexing parts with tight tolerances and great completions.