Introduction

Welcome to the universe of visual precision , where Machine Vision Systems (MVS) upset enterprises through cutting-edge imaging and examination capacities. These complex systems leverage cutting-edge imaging technologies and advanced algorithms to replicate human visual capabilities, enabling machines to interpret and respond to visual information with remarkable accuracy. Join us as we delve into the fascinating world of machine vision systems, exploring their complexities, applications, and extraordinary effects on visual precision.

Outline

- Introduction

- Background

- Understanding Machine Vision Systems

- Key Components and Technologies

- Applications Across Industries

- Advantages and Challenges

- Conclusion

- FAQs

Background

Understanding Machine Vision Systems

Machine Vision Systems use imaging sensors, calculations, and handling procedures to catch, dissect, and decipher visual data for computerized navigation and quality control.

Key Components and Technologies

Investigate the critical parts and innovations that involve machine vision systems, including:

Imaging Sensors: Cameras and optical devices capture visual data.

Processing Algorithms: High level calculations break down visual information to recognize examples, imperfections, or inconsistencies.

Computing Hardware: Superior execution registering equipment processes huge volumes of visual information progressively.

Integration Software: Programming stages coordinate MVS with existing systems for consistent activity and information trade.

Applications Across Industries

Find out how machine vision systems are used across assorted businesses, including:

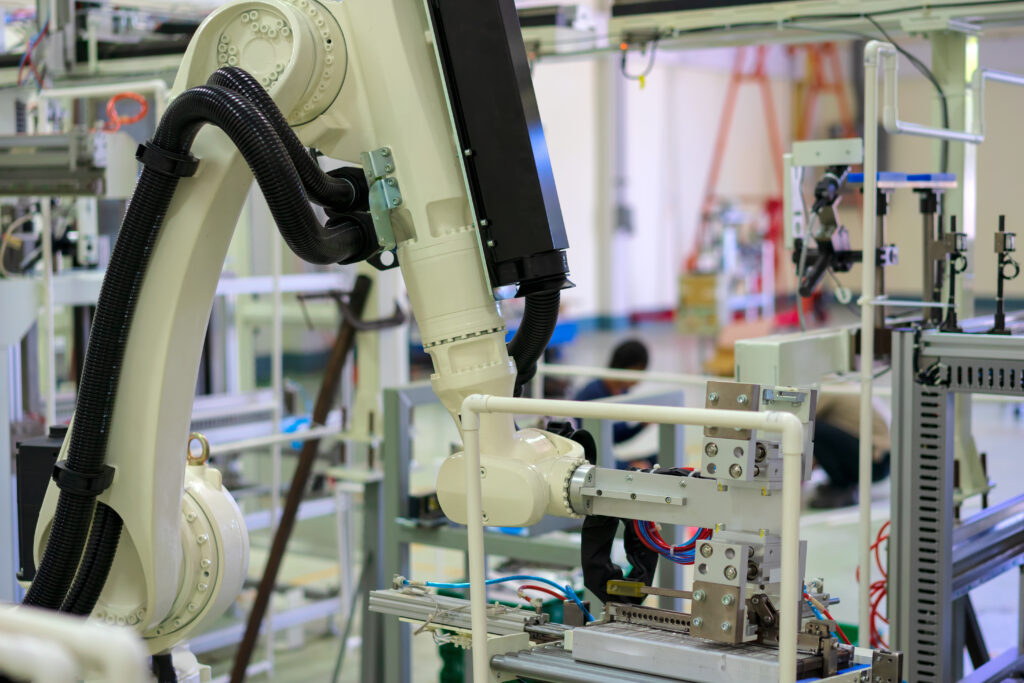

Manufacturing: MVS performs quality control assessments, deformity discovery, and get to-gether confirmation in assembling processes.

Automotive: Car enterprises use MVS for part recognizable proof, get together examination, and independent vehicle direction.

Healthcare: MVS aids clinical imaging, pathology investigation, and a careful route for persistent consideration.

Retail: Retail areas use MVS for inventory management.

Advantages and Challenges

While Machine Vision Systems offer various benefits, or example,

High Precision: MVS offers unmatched accuracy in visual inspection tasks. This leads to better product quality and fewer errors.

Speed and Efficiency: Automated visual inspections by MVS are much faster and more efficient than manual ones. This results in increased productivity.

Cost and Complexity: Carrying out and keeping up with MVS can be exorbitant and complex, requiring specific skills and systems.

Conclusion

In conclusion, machine vision systems are at the heart of modern industrial automation, providing unparalleled visual precision and efficiency across numerous sectors. As technology continues to advance, the role of machine vision will become even more critical, driving innovation and optimization in our increasingly digital world.

FAQs

1. How do Machine Vision Systems benefit manufacturing processes?

Machine vision systems perform quality control examinations. This leads to better product quality and fewer production errors.

2. What challenges are associated with implementing Machine Vision Systems?

Difficulties incorporate high beginning expenses, intricacy in system coordination, and the requirement for specific skills in conveying and keeping up with Machine Vision systems.

3. What industries can benefit from the adoption of Machine Vision Systems?

Enterprises like assembling, cars, medical services, and retail can profit from the reception of Machine Vision Systems for undertakings including quality control, part distinguishing proof, clinical imaging, and stock administration.