Introduction

In the domain of automation, Programmable Rationale Regulators (PLCs) assume a crucial role in organizing complex assembly processes with unmatched accuracy and productivity. This article digs into the meaning of PLC programming in automation, featuring its extraordinary effect on present-day modern activities.

Outline

- Introduction

- Background

- Understanding Programmable Logic Controllers (PLCs)

- Importance of PLC Programming in Automation

- Key Components of PLC Systems

- PLC Programming Languages

- Applications of PLC Programming

- Challenges and Considerations

- Future Trends in PLC Programming

- Conclusion

- FAQs

Background

Programmable Logic Controllers (PLCs) are the core of PLC programming technology, acting as the brains behind automated systems in various industries. Understanding the basics of PLC programming is essential for grasping its crucial role in streamlining manufacturing processes and improving efficiency.

Understanding Programmable Logic Controllers (PLCs)

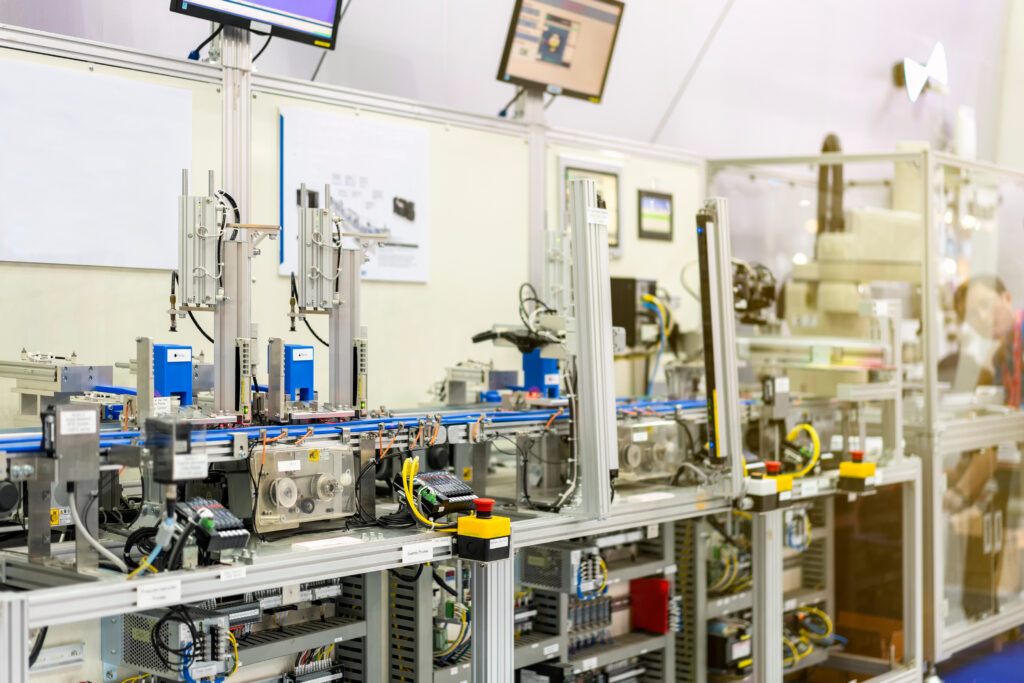

PLCs are specialized computing devices designed to control and monitor industrial machinery and processes. They follow logic-based instructions to automate tasks typically done by human operators, ensuring precision and reliability in manufacturing operations.

Importance of PLC Programming in Automation

PLC programming allows engineers to design control algorithms that manage automated systems. By programming PLCs, manufacturers can achieve seamless integration of equipment, real-time monitoring, and precise task execution, leading to improved efficiency and quality.

Key Components of PLC Systems

PLC systems consist of several key components, including input/output modules, central processing units (CPUs), memory units, communication interfaces, and software. Each component plays a crucial role in the functionality and performance of the PLC system.

PLC Programming Languages

PLC programming languages vary based on the manufacturer and application requirements. Common programming languages include ladder logic, function block diagram (FBD), structured text (ST), and sequential function chart (SFC), each suited for different programming tasks and preferences.

Applications of PLC Programming

PLC programming tracks down broad applications across assorted ventures, including producing, cars, drugs, food handling, and energy. From controlling creation lines to managing temperature and strain in modern cycles, PLCs empower the exact mastering of PLC programming in different applications.

Challenges and Considerations

While PLC programming offers many benefits, it also comes with challenges such as complexity in programming, troubleshooting, and system integration. Addressing these challenges requires specialized skills, thorough testing, and continuous improvement to ensure optimal performance.

Future Trends in PLC Programming

The eventual fate of PLC programming holds energizing prospects, with progressions in regions like cloud networks, edge processing, and AI. These patterns vow to upgrade the abilities of PLCs, empowering more brilliant and versatile mastering PLC programming answers for Business 4.0.

Conclusion

PLC programming is a cornerstone of modern automation, enabling industries to achieve high levels of precision, efficiency, and reliability in manufacturing processes. By using PLC technology and adopting emerging trends, businesses can unlock new opportunities for growth and competitiveness in a fast-changing environment.

FAQs

1. What is PLC programming, and why is it important in automation?

PLC programming includes making rationale-based guidelines to control modern apparatus and cycles, guaranteeing productive and dependable mastering of PLC programming.

2. What are the main components of a PLC system?

Key parts incorporate information/yield modules, focal handling units (central processors), memory units, correspondence connection points, and programming.

3. Which programming languages are commonly used in PLC programming?

Common languages include ladder logic, function block diagrams (FBD), structured text (ST), and sequential function charts (SFC), each suitable for specific programming tasks.

4. What are some typical applications of PLC programming?

Modern PLC programming uses logic-based design in various industries for tasks like controlling production lines, setting equipment parameters, and real-time monitoring of industrial processes.

5. What challenges do engineers face when programming PLCs?

Difficulties might include intricacy in programming, investigating, framework combination, and staying aware of advancing advancements.