Introduction

The integration of robots is fast changing the production landscape, ushering in a new era of efficiency, accuracy, and creativity. As more sectors adopt automation, robots are not only improving production capacity but also altering labor dynamics and economic models. This integration is propelling progress in smart factories, where networked systems and intelligent equipment work together seamlessly to streamline operations, cut costs, and enhance quality. “The Future of Manufacturing: Robotics Integration Insights” looks into these revolutionary developments, providing a detailed overview of how robotics is reshaping the manufacturing scene and what this implies for the industry.

Outline

- Introduction

- Background

- Understanding Robotics Integration

- Evolution and Adoption

- Key Components and Technologies

- Challenges and Solutions

- Applications Across Industries

- Real-World Implementations

- Advantages and Benefits

- Future Prospects

- Conclusion

- FAQs

Background

Robotics integration addresses a vital change in assembling, utilizing computerization to streamline functional cycles and drive extraordinary degrees of productivity and accuracy.

Understanding Robotics Integration

Robotics integration includes consistently integrating automated frameworks into assembly processes, empowering assignments to be performed with uplifted exactness, speed, and unwavering quality.

Evolution and Adoption

From customary mechanical production systems to cutting-edge, savvy plants, robotics integration has developed quickly, acquiring broad reception across ventures and changing assembly strategies.

Key Components and Technologies

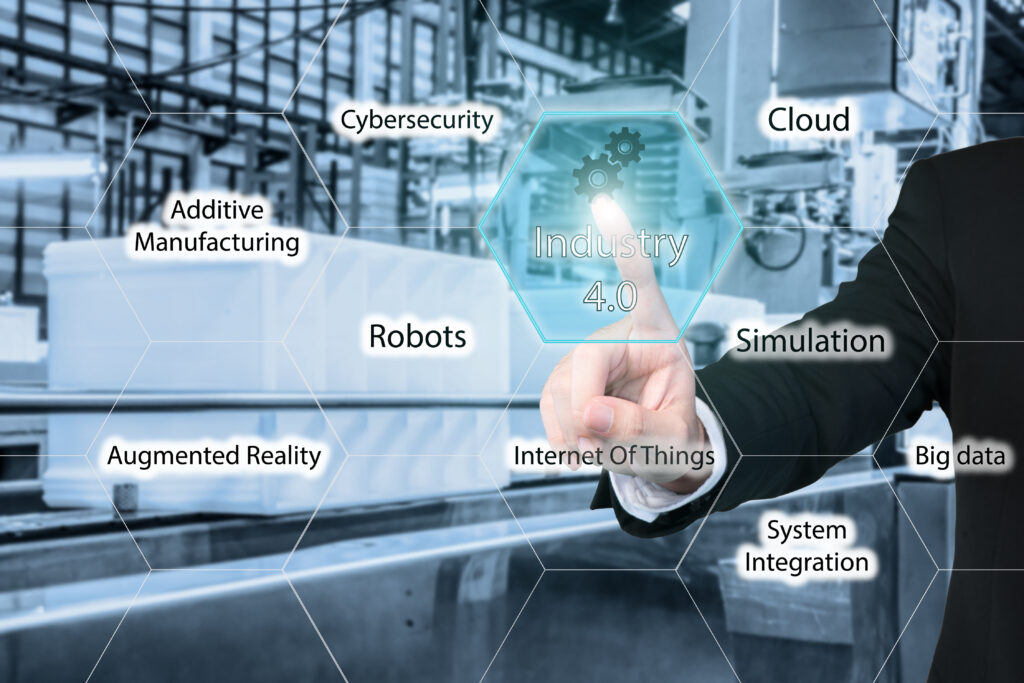

Basic parts of robotics integration incorporate automated arms, sensors, actuators, and refined control frameworks, increased by arising innovations like man-made consciousness and AI.

Challenges and Solutions

Challenges such as security concerns, labor force readiness requirements, and similarity issues are addressed with innovative solutions like collaborative robots and robust wellness conventions.

Applications Across Industries

Robotics integration tracks down applications across different ventures, including cars, gadgets, drugs, and buyer merchandise, upgrading processes going from creation and bundling to quality control and operations.

Real-World Implementations

Certifiable models exhibit the substantial advantages of robotics integration, displaying upgrades in proficiency, cost-viability, and item quality across assembly areas.

Advantages and Benefits

The upsides of robotics integration incorporate expanded efficiency, diminished mistakes, upgraded work environment security, and more prominent adaptability, driving huge enhancements in functional execution and seriousness.

Future Prospects

Future possibilities for robotics integration are huge, with continuous progressions in regions, for example, computerized reasoning, AI, and human-robot cooperation, ready to additionally alter fabricating cycles and capacities.

Conclusion

Robotics integration is ready to characterize the eventual fate of assembly, offering unrivaled open doors for productivity, advancement, and intensity. As innovation keeps on propelling, robotics integration will assume an undeniably crucial role in molding the assembly scene.

FAQs

1. What is robotics integration, and why is it important in manufacturing?

Robotics integration includes integrating automated frameworks into assembly cycles to upgrade proficiency, efficiency, and accuracy, driving critical enhancements in functional execution.

2. What industries benefit from robotics integration?

Industries such as automotive, electronics, pharmaceuticals, and consumer goods benefit from robotics integration, enhancing various assembly processes and workflows.

3. What are the key challenges in robotics integration?

Challenges include compatibility issues, safety concerns, and workforce training requirements, addressed through innovative solutions and rigorous protocols.

4. What are the advantages of robotics integration in manufacturing?

Benefits include increased productivity, fewer errors, improved workplace security, and more flexibility, which encourages focus on functional execution and intensity.

5. What are the future prospects for robotics integration in manufacturing?

Future possibilities include headways for computerized reasoning, AI, and human-robot coordinated effort, driving further advancement and productivity in assembly processes.