Introduction

Welcome to the domain of precision designing – Precision machining processes address the zenith of craftsmanship and precision in current assembling, directing ventures through the complicated course of making parts with demanding accuracy. In this article, we set out on an excursion to investigate the complexities of machining processes, their importance, and their application in certifiable situations.

Outline

- Introduction

- Background

- Understanding Precision Machining Processes

- Key Techniques and Methods

- Applications Across Industries

- Advantages and Challenges

- Conclusion

- FAQs

Background

Understanding Precision Machining Processes

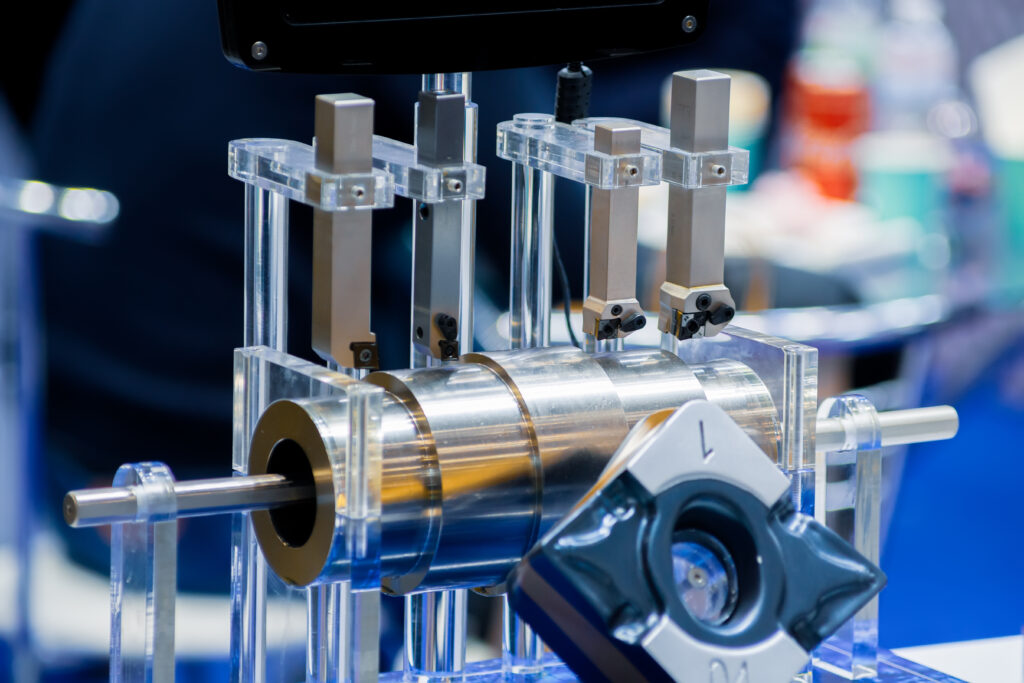

Precision Machining processes include the exact expulsion of material from a workpiece to accomplish explicit aspects, tight tolerances, and predominant surface completions. These processes require advanced apparatus, talented administrators, and careful meticulousness to guarantee ideal outcomes.

Key Techniques and Methods

Investigate the fundamental strategies and techniques indispensable to the precision process:

- CNC Machining: Computer Numerical Control (CNC) machining uses computer-controlled machinery to execute exact device developments, empowering the creation of unpredictable parts with remarkable precision.

- Turning and Milling: Turning and processing tasks include the revolution of a work piece against a slicing device to shape and frame it into the ideal math, accomplishing exact aspects and surface completions.

- Grinding and Finishing: The crushing and finishing processes refine the surface and layered exactness of machined parts, guaranteeing adherence to severe particulars.

- EDM Machining: Electrical Discharge Machining (EDM) uses electrical releases to disintegrate material from the work piece , empowering the production of multifaceted elements and shapes with high accuracy.

Applications Across Industries

Find the different utilizations of the precision Process across different businesses, including:

- Aerospace: Precision machined parts are basic for airplane motors, airframes, and flight control frameworks, where unwavering quality, execution, and security are paramount.

- Medical: These processes are fundamental for assembling careful instruments, inserts, and clinical gadgets with exact aspects and complex highlights, guaranteeing ideal usefulness and patient security.

- Automotive: Precision machined parts are vital to car fabrication for motors, transmissions, and suspension frameworks, where solidity, effectiveness, and execution are key considerations.

- Electronics: Precision Machining assumes a critical role in hardware fabrication for delivering parts, for example, connectors, heat sinks, and lodgings with tight tolerances and complex calculations.

Advantages and Challenges

- Unparalleled Precision and Accuracy: Machining processes empower the creation of parts with micron-level resistances. They involve intricate calculations and produce unrivaled surface finishes. These meet the demanding prerequisites of various industries.

- Versatility and Flexibility: The machining process can oblige many materials, sizes, and shapes, offering flexibility and adaptability in part fabricating.

- Cost and Complexity: Carrying out and overseeing machining processes requires investment in cutting-edge gear. It also demands skilled work and thorough quality control measures. These present difficulties to cost-viability and versatility.

Conclusion

The precision machining process acts as the foundation of current assembling, directing ventures toward precision and greatness. As businesses proceed to advance and enhance, precision machining processes remain fundamental. They explore the way to accomplish unparalleled degrees of precision and quality.

FAQs

1. What are precision machining processes?

It includes the exact expulsion of material from a workpiece to accomplish explicit aspects, tight tolerances, and prevalent surface finishes.

2. What industries rely on precision machining processes?

Businesses like aviation, clinical, auto, and gadgets depend on the precision machining process for the development of basic parts.

3. What are the benefits of precision machining processes?

Precision machining advancements offer benefits like unmatched precision and accuracy. They also enhance efficiency and effectiveness. Additionally, they enable the production of parts with superior performance and reliability. These advancements drive innovation and progress across industries.