Introduction

In the domain of accuracy, designing is everything. Control panel design assumes a vital role in guaranteeing the consistent activity of accuracy hardware, giving the important controls and connection points for exact checking and change. This article dives into the meaning of control panel design in precision engineering, featuring its role in enhancing execution and accomplishing unmatched precision.

Outline

- Introduction

- Background

- Evolution of Control Panel Design in Precision Engineering

- Key Components and Features

- Technological Advancements

- Benefits of Precision Control Panel Design

- Challenges and Solutions

- Conclusion

- FAQs

Background

Evolution of Control Panel Design in Precision Engineering

Control panel design has evolved from simple changes to refined interfaces custom-made to the particular prerequisites of accuracy in designing applications.

Key Components and Features

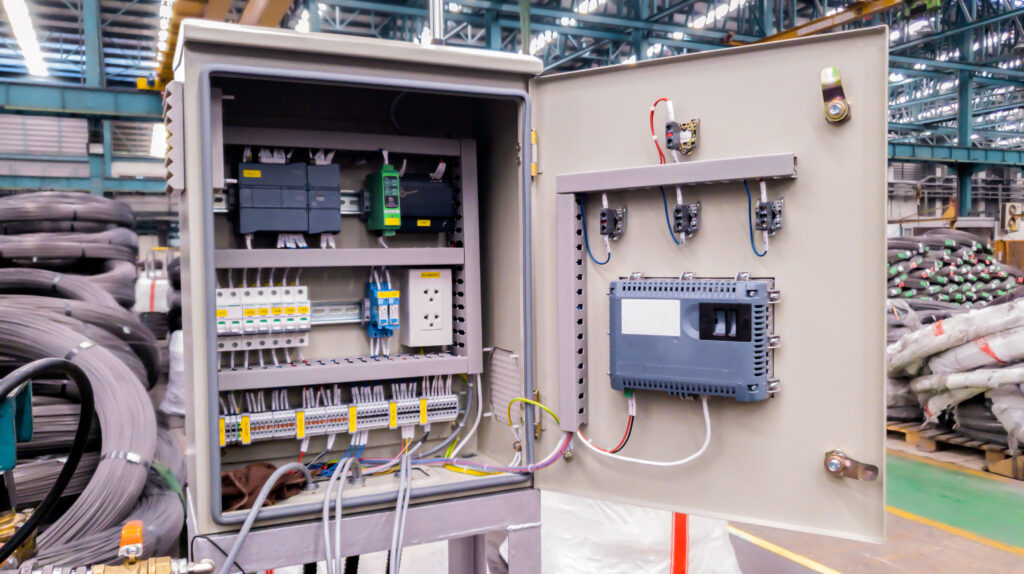

Investigate the critical parts and highlights that characterize accuracy control panel design:

- High-Precision Interfaces: Control panels include high-goal shows and exact controls, empowering administrators to make minute changes with precision.

- Integration with Precision Machinery: Consistent mixing with accuracy apparatus takes into consideration synchronized control and checking, guaranteeing ideal execution.

- Customizable Configurations: Control panels offer adaptable designs to accommodate changing functional requirements and inclinations.

- Real-Time Data Visualization: High level information perception capacities give continuous bits of knowledge into machine execution, considering proactive changes and advancements.

Technological Advancements

Find the most recent mechanical headways driving accuracy control panel design:

- IoT Connectivity: Coordination with IoT advances empowers remote checking and prescient support, streamlining machine uptime and execution.

- Augmented Reality (AR) Interfaces: AR interfaces overlay constant information onto the actual climate, improving administrator situational mindfulness and working with exact control.

- Machine Learning Algorithms: AI calculations break down information examples to advance control systems and foresee upkeep needs, guaranteeing nonstop improvement in accuracy in designing cycles.

Benefits of Precision Control Panel Design

Investigate the advantages that accuracy control panel design brings to accuracy designing:

- Unparalleled Accuracy: Exact controls and ongoing observation empower administrators to accomplish unparalleled degrees of exactness in their designing cycles.

- Enhanced Productivity: Smoothed out interfaces and natural controls limit personal time and streamline work process effectiveness, expanding, generally speaking, efficiency.

- Improved Quality Assurance: Constant information perception and investigation instruments engage administrators to recognize and resolve quality issues quickly, guaranteeing a reliably excellent result.

- Future-Proofing: Versatile and versatile plans future-confirmation accuracy in designing tasks, taking into account the consistent coordination of arising advances and cycles.

Challenges and Solutions

Address the difficulties related to accuracy control panel design and techniques for conquering them:

- Complexity of Integration: Incorporating assorted advances and frameworks can be perplexing. A close joint effort between specialists, producers, and providers is fundamental to guaranteeing consistent incorporation and interoperability.

- Ensuring Data Security: With an expanded network comes increased online protection gambles. Carrying out strong encryption conventions and access controls shields delicate information and forestalls unapproved access.

Conclusion

Accuracy control panel design is instrumental in streamlining execution, exactness, and efficiency in accuracy designing applications. By utilizing state of the art advances, embracing best practices, and tending to difficulties proactively, organizations can open the maximum capacity of accuracy control panel arrangements and drive greatness in accuracy designing.

FAQs

1. How does precision control panel design contribute to accuracy in precision engineering?

Accuracy control panel design empowers administrators to make exact changes and screen machine execution progressively, guaranteeing unmatched degrees of exactness in accuracy designing cycles.

2. What are some of the latest technological advancements driving precision control panel design?

Mechanical headways incorporate an IoT network for remote checking, AR interfaces for upgraded situational mindfulness, and AI calculations for prescient upkeep and improvement.

3. How can businesses address the complexity of integrating precision control panel systems with existing infrastructure?

Nearby coordinated effort between designing groups, producers, and providers is fundamental for consistent combination and interoperability. Careful testing and approval methods help recognize and determine coordination challenges successfully.