Introduction

Automated manufacturing processes have revolutionized industries by streamlining production, enhancing efficiency, and reducing operational costs. This article delves into the realm of automated manufacturing, exploring its various processes, applications, and benefits.

Outline

- Introduction

- Background

- Understanding Automated Manufacturing

- Key Components and Technologies

- Applications Across Industries

- Advantages and Benefits

- Implementation Challenges

- Future Outlook

- Conclusion

- FAQs

Background

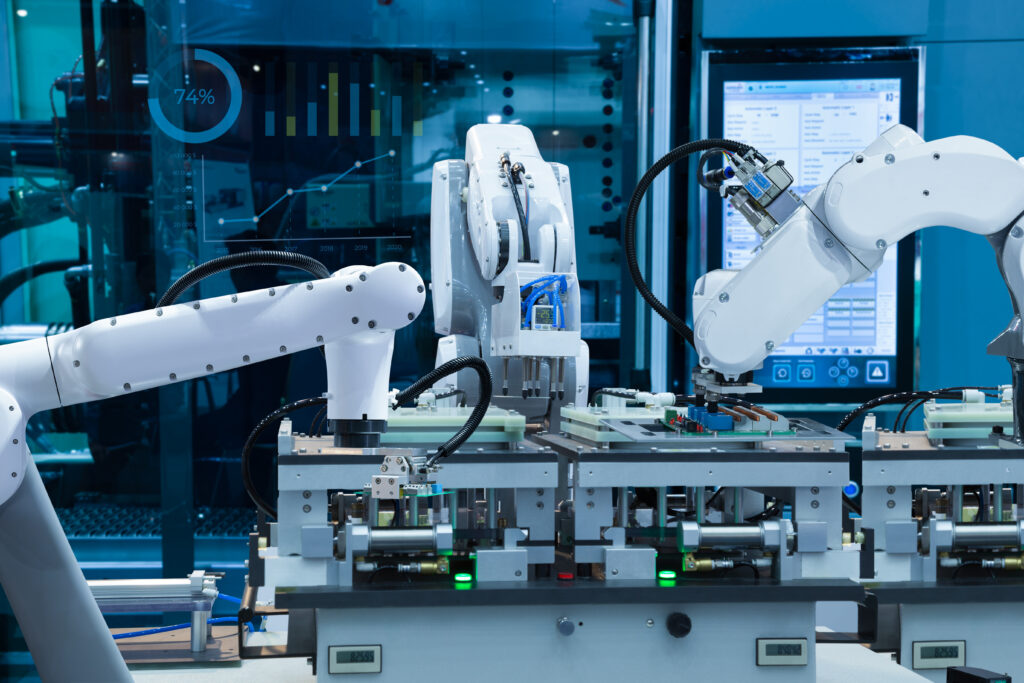

Automated manufacturing involves using advanced technologies such as robotics, artificial intelligence (AI), the Internet of Things (IoT), and machine learning to automate production processes. This section provides an overview of automated manufacturing and its evolution over time.

Understanding Automated Manufacturing

To achieve automated manufacturing, various components and technologies are used, including industrial robots, automated guided vehicles (AGVs), sensors, actuators, control systems, and software solutions. This section explores these key components and their roles in automated manufacturing processes.

Key Components and Technologies

Automated manufacturing is applied across various industries, including automotive, aerospace, electronics, pharmaceuticals, food and beverage, and consumer goods. This section highlights specific examples of automated manufacturing processes in each industry.

Advantages and Benefits

Automated manufacturing offers numerous advantages, such as increased efficiency, improved product quality, enhanced safety, reduced labor costs, and greater flexibility in production. This section elaborates on the significant benefits gained from automated manufacturing processes.

Implementation Challenges

While the advantages of automated manufacturing are substantial, implementing these processes can present challenges such as high initial investment costs, workforce training, and integration issues. This section examines common challenges and strategies to overcome them.

Future Outlook

The future of automated manufacturing promises continued growth and advancement. This section explores emerging trends such as collaborative automation, digitalization, additive manufacturing, and sustainable practices, shaping the future landscape of production.

Conclusion

In conclusion, automated manufacturing processes represent the pinnacle of modern industrial innovation, driving efficiency, productivity, and competitiveness. By embracing automation, industries can unlock new opportunities for growth, innovation, and sustainable development.

FAQs

1. What is automated manufacturing, and how does it work?

Automated manufacturing refers to the use of advanced technologies in production processes, reducing human intervention and enhancing productivity. It integrates various components such as robots, sensors, actuators, and control systems to perform tasks autonomously.

What are the advantages of automated manufacturing?

The upsides of automated manufacturing fabrication include expanded efficiency, further developed item quality, upgraded well-being, decreased work costs, and more noteworthy adaptability during booking and customization.

3. What industries benefit from automated manufacturing?

Automated manufacturing production processes track down applications across many businesses, including cars, aviation, gadgets, drugs, food and refreshments, and shopper merchandise.

4. What are the challenges associated with implementing automated manufacturing processes?

Difficulties might include high introductory venture costs, automated manufacturing, labor force preparation, reconciliation issues, and network protection chances.

5. What are some emerging trends in automated manufacturing?

Emerging trends include collaborative robotics, digitalization, additive manufacturing (3D printing), sustainable automated manufacturing practices, and the integration of artificial intelligence and machine learning.