Introduction

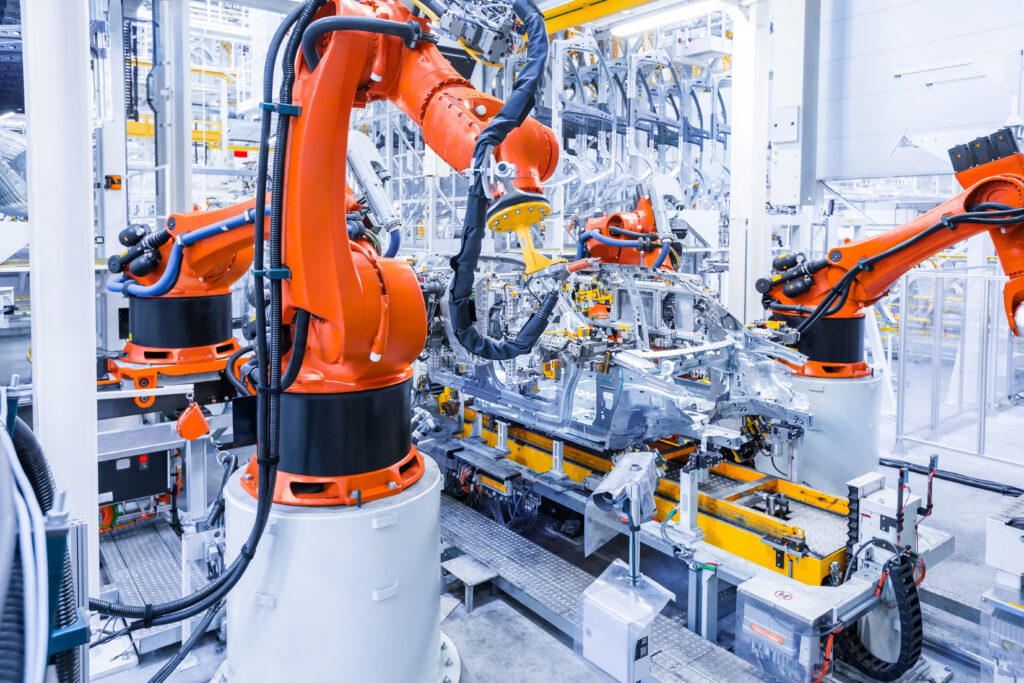

“Efficiency Redefined: The Power of Assembly Line Automation” examines how advanced automation technologies are transforming manufacturing processes. Assembly line automation is transforming the industry by combining modern robots, intelligent systems, and cutting-edge software. This introduction examines the dramatic influence of these developments on productivity, quality, and competitiveness, providing a look into a future in which manufacturing is quicker, smarter, and more efficient than ever before.

Outline

- Introduction

- Background

- Advancement of assembly line automation in assembling

- Effects of sequential construction system

- Key innovations driving assembly line automation

- Contextual analyses exhibiting achievement

- Future trends and prospects

- Conclusion

- FAQs

Background

Assembly line automation combines advanced technologies with production system automation to streamline assembly processes and improve operational efficiency. This section provides basic information on the principles and development of assembly line automation systems.

Advancement of assembly line automation in assembling

The development of assembly line automation in manufacturing has seen continuous growth. It started to the introduction of conveyor belts and progressed to the implementation of advanced automation systems. This section traces the historical evolution of assembly line automation and its impact on the manufacturing industry.

Effects of sequential construction system assembly line automation

Assembly line automation has led to numerous benefits, such as increased productivity, improved product quality, reduced labor costs, enhanced safety, and greater flexibility. This section explores the transformative impacts of assembly line automation on modern industries.

Key innovations driving assembly line automation

Several key technologies drive assembly line automation, including automation systems, artificial intelligence, machine learning, IoT networks, and advanced control systems. This section discusses how these innovations contribute to redefining efficiency in manufacturing.

Contextual analyses exhibiting achievement

Case studies showcase successful assembly line automation, showing real examples of companies improving productivity, cost-effectiveness, advanced automation, and competitiveness.

Future patterns and prospects

The fate of assembly line automation production system assembly line automation holds promising possibilities, for example, the combination of savvy fabricating advances, the ascent of cooperative sequential construction system automation, prescient upkeep, and independent creation frameworks. This segment investigates arising patterns and their expected effect on the business.

Conclusion

In conclusion, assembly line automation has redefined manufacturing efficiency, driving exceptional productivity and growth. By adopting automation advancements, companies can stay competitive in an increasingly dynamic, technology-driven landscape.

FAQs

1. What is assembly line automation?

Assembly line automation uses advanced technologies to automate manufacturing processes and streamline production.

2. What are the benefits of assembly line automation?

The advantages incorporate expanded efficiency, further developed item quality, diminished work costs, improved security, and more noteworthy adaptability.

3. What technologies drive assembly line automation?

Key technologies driving assembly line automation include automation systems, artificial intelligence, machine learning, IoT connectivity, and advanced control systems.

4. How can businesses benefit from assembly line automation?

Organizations can benefit from assembly line automation by achieving higher efficiency, reducing costs, improving quality, and remaining competitive in the market.

5. What are the future trends in assembly line automation?

Future trends include the integration of smart manufacturing technologies, collaborative automation, production system automation, predictive maintenance, and autonomous production systems.