Introduction

In today’s fast-paced industrial world, efficiency is key to staying competitive. This article looks at how programmable logic controllers (PLC) and effective programming techniques can streamline operations, boost productivity, and drive progress in various industries.

Outline

- Introduction

- Background

- Understanding the Role of PLCs in Industrial Automation

- Fundamentals of PLC Programming

- Optimizing Operations with Advanced PLC Techniques

- Future Trends in PLC Programming and Industrial Automation

- Conclusion

- FAQs

Background

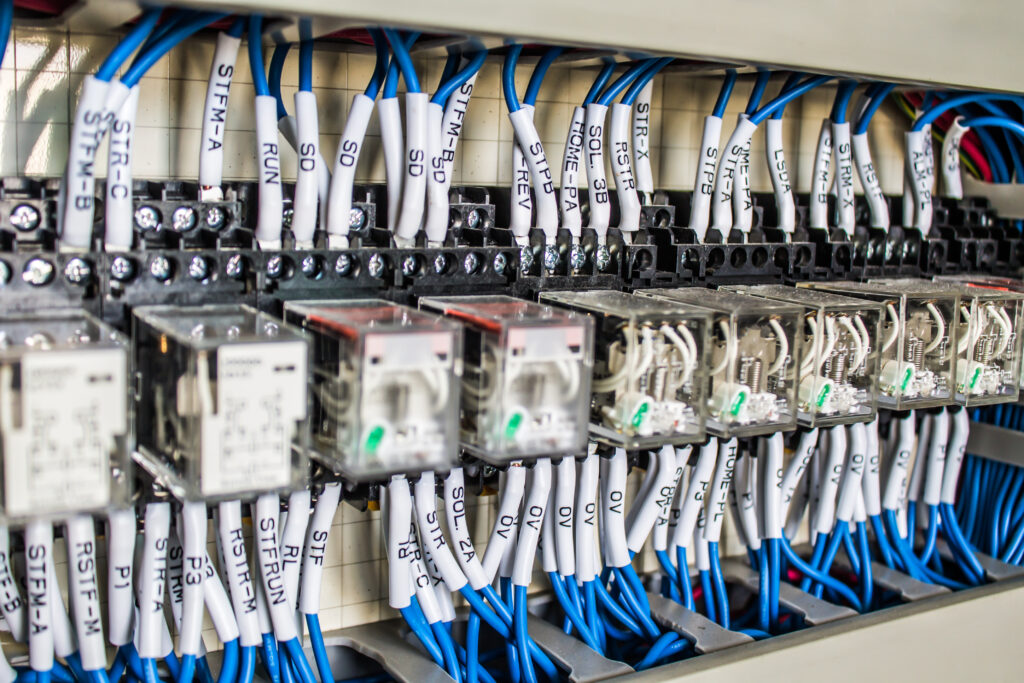

PLCs are the backbone of modern automation, providing reliable control solutions for manufacturing processes, machinery, and equipment. This section gives an overview of PLCs, their development, and their importance in today’s industrial settings.

Understanding the Role of PLCs in Industrial Automation

Effective PLC programming is essential for achieving operational efficiency. This section covers the basics of PLC programming, including ladder logic, input/output handling, programming languages, and common programming techniques.

Fundamentals of PLC Programming

Advanced PLC techniques help engineers optimize operations and maximize efficiency. Topics include motion control, PID loops, data handling, networking, and integration with other PLC systems.

Optimizing Operations with Advanced PLC Techniques

Certifiable contextual analyses feature how PLC writing computer programs are applied to tackle explicit difficulties and further develop effectiveness in different ventures, for example, auto fabrication, food handling, and drug creation.

Future Trends in PLC Programming and Industrial Automation

The fate of PLC-written computer programs is molded by arising patterns, for example, edge figuring, IoT combination, cloud availability, and AI. This segment investigates what these patterns will mean for PLC programming and modern mastery of PLC programming.

Conclusion

In conclusion, PLC programming is crucial for streamlining operations and driving efficiency in industrial settings. By mastering PLC programming basics, exploring advanced techniques, and adopting emerging technologies, companies can achieve sustainable growth and a competitive edge.

FAQs

1. What is a PLC, and how does it contribute to operational efficiency?

A PLC is a specific PC used to control modern cycles and hardware. Its capacity to execute control calculations and computerize undertakings adds to functional productivity by decreasing manual mediation and advancing cycles.

2. What are some common programming languages used in PLC programming?

Normal PLC programming dialects incorporate stepping stool rationale, organized text, capability block graphs, and consecutive capability diagrams.

3. How can PLC programming be applied to optimize specific industrial processes?

Engineers can use PLC programming to improve industrial processes by automating tasks, implementing control algorithms for precise operation, and integrating various systems for seamless communication and coordination.

4. What are the key considerations for implementing PLC programming solutions in industrial settings?

Key considerations include understanding the specific requirements of the application, choosing the right hardware and software, designing robust control algorithms, and ensuring proper testing and validation before deployment.