Introduction

CNC drill technology has redefined drilling operations across various industries, providing precision, efficiency, and versatility. This article explores the world of CNC drills, examining their significant impact on drilling performance.

Outline

- Introduction

- Background

- Grasping CNC Drills

- Development of CNC Drilling Innovation

- Benefits of CNC Drills

- Uses of CNC Drilling

- Future Patterns and Developments

- Conclusion

- FAQs

Background

Drilling processes were typically challenging and prone to errors. However, with the introduction of CNC drills, drilling tasks have seen a significant shift, offering increased accuracy and efficiency.

Grasping CNC Drills

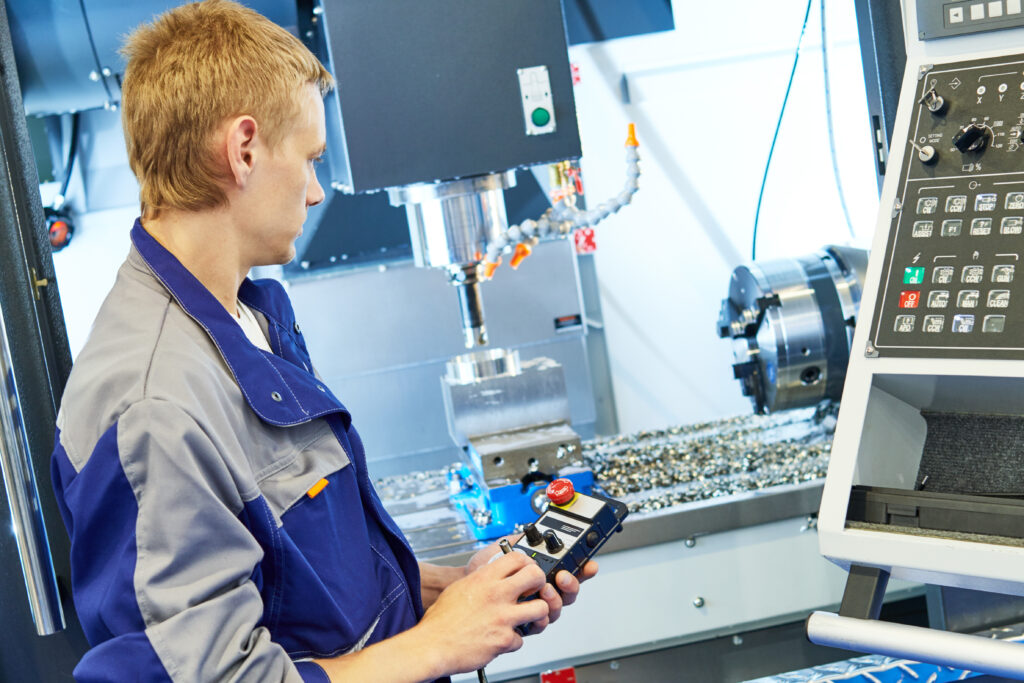

CNC drills are machines controlled by computer programs to perform precise drilling tasks. These drills use rotating bits to remove material from workpieces according to customized instructions, ensuring consistent and accurate hole creation.

Development of CNC Drilling Innovation

The development of CNC drilling innovation has been surprising, set apart by headways in control frameworks, shaft paces, and exactness. Present-day CNC drills gloat refined highlights that upgrade drilling tasks, bringing about expanded proficiency and unwavering quality.

Benefits of CNC Drills

CNC drills offer numerous benefits, including improved precision, repeatability, and efficiency. They enable the creation of complex hole patterns with minimal human intervention, thereby reducing errors and enhancing overall productivity.

Uses of CNC Drilling

Applications for CNC drill infiltration can be found in a variety of fields, such as aviation, automotive, intelligence, and construction. It is used to create holes in a wide range of materials, including composites, metal, wood, and plastic, while giving careful consideration to a wide range of incoming requirements. Future patterns and developments.

Future Patterns and Developments

The future of CNC drilling is characterized by continuous innovation and technological advancements. Key trends include the integration of smart sensors for real-time monitoring, the development of adaptive drilling algorithms, and the adoption of multi-axis drilling systems.

Conclusion

In conclusion, CNC drills have transformed drilling operations, providing unmatched accuracy, efficiency, and flexibility. As technology continues to advance, CNC drilling will play a crucial role in driving innovation and shaping the future of drilling processes.

FAQs

1. What is CNC drilling, and how can it work?

CNC drilling involves the use of computer-controlled machines to create holes in workpieces using rotating drills, following programmed instructions for precise hole creation.

2. What are the primary benefits of CNC drills?

The primary benefits incorporate expanded precision, repeatability, efficiency, and the capacity to execute complex drilling assignments with insignificant human intervention.

3. In which enterprises are CNC bores generally utilized?

CNC drills find applications in ventures like aviation, cars, assembling, and development, taking special care of different drilling necessities across assorted materials.

4. What are a few future patterns in CNC boring innovation?

Future trends include the integration of smart sensors, the development of adaptive drilling algorithms, and the advancement of multi-axis drilling systems for enhanced performance.

5. How might organizations profit from embracing CNC drill innovation?

Organizations can profit from further developed effectiveness, diminished lead times, higher accuracy, and the capacity to embrace a large number of drilling tasks with more prominent exactness and unwavering quality.