Introduction

Assembly line automation has transformed manufacturing industries by optimizing production processes, boosting efficiency, and reducing operational costs. This article delves into the realm of assembly line automation, exploring its significance, implementation, and benefits.

Outline

- Introduction

- Background

- Understanding assembly line automation

- Applications across industries

- Advantages and benefits

- Implementation challenges

- Future outlook

- Conclusion

- FAQs

Background

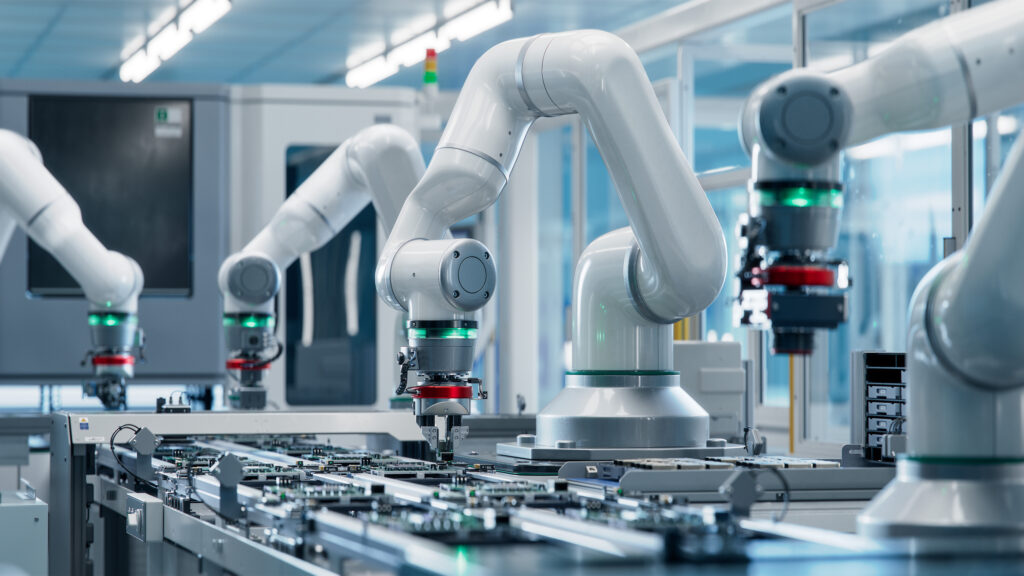

Assembly line automation involves using advanced technologies such as robotics, conveyors, sensors, and control systems to automate production tasks traditionally performed by human workers. This section provides an overview of assembly line automation and its evolution over time.

Understanding assembly line automation

To achieve automation in automotive production lines, various components and technologies are used, including industrial automation, automated guided vehicles (AGVs), conveyor systems, vision systems, and programmable logic controllers (PLCs). This section explores these key components and their roles in assembly line automation.

Applications across industries

Assembly line automation is used across various industries, including automotive, electronics, aerospace, consumer goods, and pharmaceuticals. This section highlights specific examples of automated assembly processes in each industry.

Advantages and benefits

Assembly line automation offers numerous benefits, such as increased efficiency, improved product quality, enhanced safety, reduced labor costs, and faster time-to-market. This section elaborates on the significant advantages gained from automated assembly processes.

Implementation challenges

While the benefits of assembly line automation are substantial, implementing these systems can present challenges such as high initial investment costs, technical complexities, workforce reskilling, and integration issues. This section discusses common challenges and strategies to overcome them.

Future outlook

The future of assembly line automation promises further growth and advancement. This section explores emerging trends such as collaborative robotics, artificial intelligence, digital twinning, and sustainable automation practices, shaping the future of manufacturing.

Conclusion

In conclusion, assembly line automation represents a crucial shift in modern manufacturing, optimizing efficiency, productivity, and competitiveness. By embracing automation, industries can unlock new opportunities for growth, innovation, and sustainable development.

FAQs

1. What is assembly line automation, and how does it work?

Assembly line automation refers to the use of advanced technologies to automate production processes on assembly lines, reducing human intervention and enhancing efficiency.

2. What are the advantages of assembly line automation?

The advantages of assembly line automation include increased efficiency, improved product quality, enhanced safety, reduced labor costs, and faster time-to-market for products.

3. What industries benefit from assembly line automation?

Mechanical production system assembly line automation tracks down applications across different enterprises, including cars, gadgets, aviation, purchaser merchandise, and drugs, among others.

4. What are the challenges associated with implementing assembly line automation?

Challenges may include high initial investment costs, technical complexities, workforce training, integration issues, and ensuring compatibility with existing production processes.

5. What are some emerging trends in assembly line automation?

Emerging trends include collaborative robotics, artificial intelligence, digital twinning, predictive maintenance, and the integration of sustainable practices into assembly line automation processes.