Introduction

Precision machining remains a demonstration of the quest for flawlessness in present day fabricating, typifying the pith of precision, complexity, and greatness. In this article, we dive into the essence of precision machining, investigating its importance, procedures, and the craftsmanship engaged with tweaking flawlessness.

Outline

- Introduction

- Background

- Understanding Precision Machining

- Key Techniques and Processes

- Applications Across Industries

- Advantages and Challenges

- Conclusion

- FAQs

Background

Understanding Precision Machining:

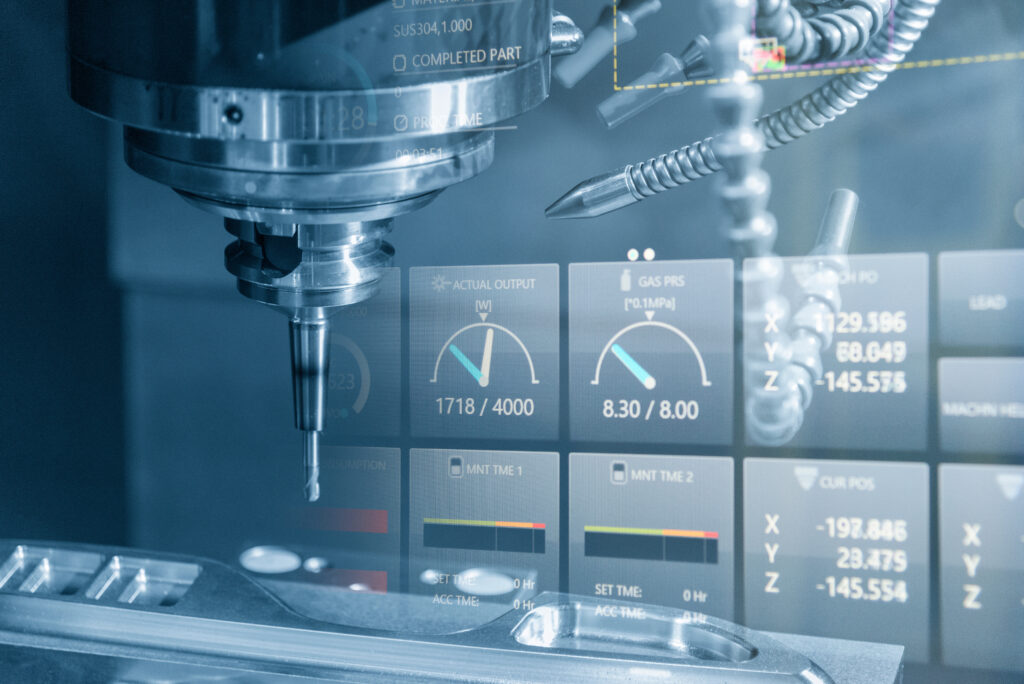

Precision machining is a careful assembling process that includes the expulsion of material from a workpiece to accomplish exact aspects, tight resistances, and immaculate surface completions. It requires advanced hardware, gifted administrators, and faithful scrupulousness to accomplish the zenith of precision.

Key Techniques and Processes

Find the fundamental methods and processes indispensable to precision machining:

- CNC Machining: Computer Numerical Control (CNC) machining uses PC controlled hardware to organize exact developments of cutting instruments, working with the creation of complex parts with unrivalled precision.

- Turning and Milling: Turning and processing tasks involve the revolution of a workpiece against a slicing instrument to shape it into the ideal shape and aspects, accomplishing faultless precision and surface completions.

- Grinding and Finishing: Crushing and completing methods refine the surface and layered precision of machined parts, guaranteeing adherence to demanding particulars and principles.

- EDM Machining: Electrical Discharge Machining (EDM) utilizes electrical flashes to shape mind boggling highlights and forms in the work piece , empowering the formation of exceptionally many-sided and exact parts.

Applications Across Industries

Investigate the assorted utilizations of precision machining across different businesses, including:

- Aerospace: Precision machined parts are basic for airplane motors, primary components, and aviation frameworks, where dependability, execution, and security are fundamental.

- Medical: Precision machining assumes a crucial role in creating clinical gadgets, inserts, and careful instruments with the most extreme precision and exactness, guaranteeing ideal usefulness and patient prosperity.

- Automotive: Precision machined parts are key to car fabricating for motors, transmissions, and frame parts, where solidity, productivity, and execution are basic.

- Electronics: Precision machining is basic to hardware production for manufacturing parts like connectors, lodgings, and intensity sinks with exact aspects and perplexing elements.

Advantages and Challenges

While Precision machining offers bunch benefits, it likewise presents difficulties, For example,

- Unrivaled Precision and Accuracy: Precision machining specializes in producing parts with micron-level tolerances, intricate geometries, and flawless surface finishes. This capability meets the rigorous requirements of various industries.

- Versatility and Flexibility: Precision machining processes handle a broad scope of materials, calculations, and specifications. This versatility and adaptability allow for flexible and efficient part production.

- Cost and Complexity: Executing and overseeing precision machining activities requires significant investment in state-of-the-art hardware. Skilled labor is essential, as well as fastidious quality control measures. These factors present challenges to cost-effectiveness and adaptability.

Conclusion

All in all, precision machining typifies the tenacious quest for flawlessness in present-day fabricating. As ventures make progress toward ever-greater degrees of precision and greatness. Precision machining remains the foundation, calibrating flawlessness and pushing the limits of what is reachable.

FAQs

1. What is precision machining?

Precision machining is a careful assembling process that includes the exact expulsion of material from a workpiece. This process aims to achieve tight resistances and perfect surface finishes.

2. What industries rely on precision machining?

Enterprises like aviation, clinical, cars, and gadgets intensely depend on precision machining for the creation of basic parts.

3. What are the benefits of precision machining?

Precision machining advancements offer benefits like unmatched precision and accuracy. They also enhance efficiency and effectiveness. Additionally, they enable the production of parts with superior performance and reliability. These advancements drive innovation and progress across industries.