Introduction

Welcome to the time of imaginative imaging. Machine Vision Systems (MVS) are at the very forefront of changing the manner in which we see and dissect visual information. In this article, we dig into the progressive effect of MVS, their functionalities, and their part in forming different enterprises.

Outline

- Introduction

- Background

- Understanding Machine Vision Systems

- Key Components and Technologies

- Applications Across Industries

- Advantages and Challenges

- Conclusion

- FAQs

Background

Understanding Machine Vision Systems

MVS joins state-of-the-art imaging innovation with cutting-edge calculations to decipher visual information, empowering robotized direction and investigation.

Key Components and Technologies

- Imaging Sensors: These sensors catch visual information with accuracy and clarity, allowing the establishment to be examined.

- Processing Algorithms: High-level calculations examine visual information, separating experiences and examples for direction.

- Computing Infrastructure: Superior execution figuring equipment processes visual information progressively, empowering fast investigation and reaction.

- Integration Software: The programming stages work with the consistent joining of MVS into existing systems and work processes, improving functional effectiveness.

Applications Across Industries

Find the different utilizations of machine vision systems across different ventures, including:

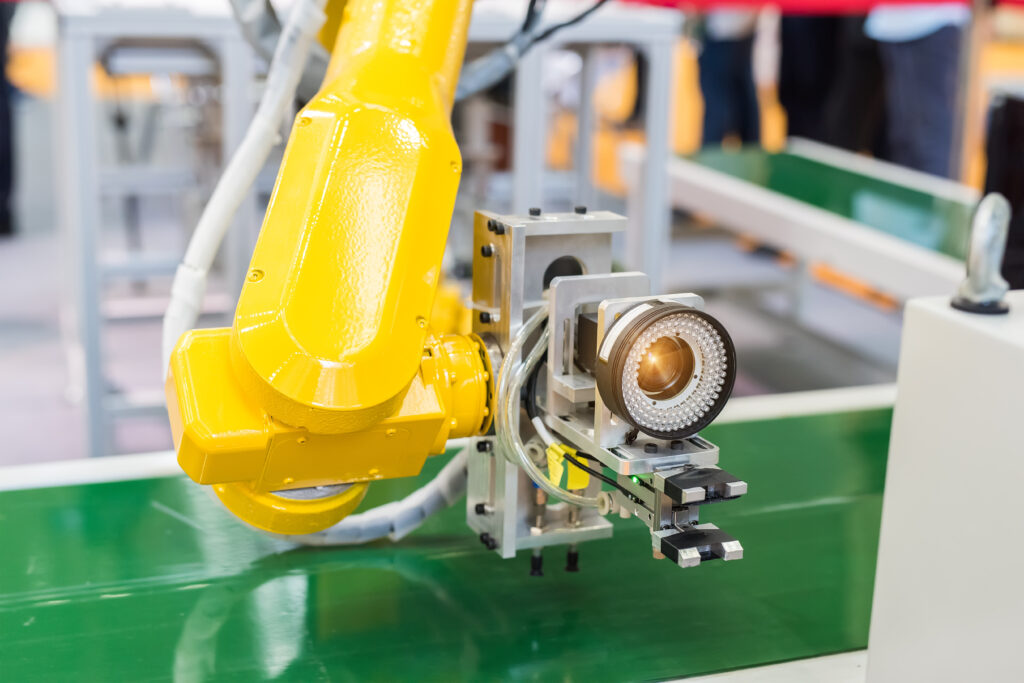

- Manufacturing: MVS conducts quality control investigations, deformity identification, and gathering checks, guaranteeing item quality and dependability.

- Automotive: MVS helps with part-distincting proof, gathering investigation, and independent vehicle direction, further developing security and productivity.

- Healthcare: MVS aids clinical imaging, diagnostics, and careful route, upgrading patient consideration and therapy results.

- Retail: MVS is used for stock administration, advancing tasks, and upgrading client encounters.

Advantages and Challenges

- Precision and Accuracy: MVS conveys exact and precise visual assessment, guaranteeing steady quality and dependability.

- Efficiency and Speed: Mechanized visual examinations by MVS are quicker and more proficient than manual reviews, improving efficiency.

- Cost and Complexity: Executing and keeping up with MVS can be exorbitant and complex, requiring particular mastery and foundation.

Conclusion

In conclusion, imaginative imaging with machine vision proclaims another period of visual examination and navigation. As associations embrace MVS and overcome difficulties, they open remarkable doors for advancement and development.

FAQs

1. How do machine systems benefit manufacturing processes?

Machine systems empower quality control reviews, deformity recognition, and gathering checks in assembling, prompting further developed item quality and diminished blunders.

2. What challenges are associated with implementing machine vision systems?

Difficulties incorporate high beginning expenses, intricacy in system joining, and the requirement for specific skills in conveying and keeping up with machine systems.

3. What industries can benefit from the adoption of machine vision systems?

Enterprises like assembling, cars, medical services, and retail can profit from machine vision systems for undertakings including quality control, part recognition, clinical imaging, and stock administration.