Introduction

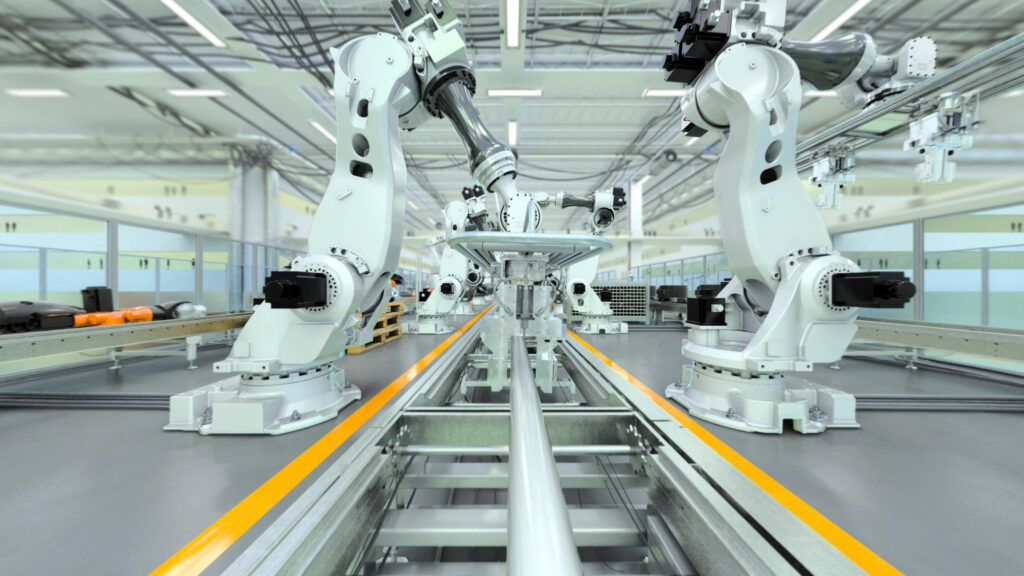

Industrial robotics have transformed assembly processes in various industries by providing innovative solutions to complex production challenges. This article looks at the different uses of industrial robots and their significant impact on modern manufacturing environments.

Outline

- Introduction

- Background

- Understanding Industrial Robotics

- Evolution of Automation in Manufacturing

- Role of Industrial Robotics in Redefining Automation

- Applications Across Industries

- Benefits and Advantages

- Future Trends

- Conclusion

- FAQs

Background

The background section provides an overview of the historical development of automated assembly and the rise of industrial robots as key drivers of progress. It looks at how robotics technology has evolved and been integrated into modern manufacturing environments.

Understanding Industrial Robotics

This part digs into the essentials of industrial robotics, including robot types, abilities, programming methods, and applications. It makes sense how industrial robotics is utilized to automate errands, streamline work processes, and further develop efficiency in different industrial areas.

Evolution of Automation in Manufacturing

The development of industrial robotics in assembly followed from the beginning of modern mechanical technology to the current period of cutting-edge mechanical technology and man-made consciousness. This segment features key achievements and innovative progressions that have formed the computerization scene.

Role of Industrial Robotics in Redefining Automation

Modern mechanical technology has had an extraordinary impact on reclassifying industrial robotics by empowering exact, effective, and adaptable creation processes. This part investigates how industrial robotics are used to computerize errands, smooth out activities, and adjust to changing creation requests.

Applications Across Industries

This part gives instances of industrial robotics applications across various businesses, like car fabrication, hardware gathering, drugs, and planned operations. It examines how modern mechanical technology is used to perform undertakings ranging from material handling and gathering to examination and bundling.

Benefits and Advantages

Industrial robotics offer various advantages and benefits, including expanded efficiency, further developed quality, upgraded working environment well-being, and cost reserve funds. This part examines the substantial advantages that mechanical technology and industrial robotics bring to organizations, for example, decreased process durations, limited mistakes, and streamlined asset use.

Future Trends

We examine the future of industrial robotics, focusing on emerging trends like collaborative robots, AI-driven robotics, and the integration of robotics with other advanced technologies. This section explores how these trends will shape the future of manufacturing and drive further progress in industrial robotics.

Conclusion

All in all, modern mechanical technology applications conscientiously advance and extend, driving development and change in assembling. Embracing advanced mechanics innovation empowers organizations to overcome creation challenges, further develop seriousness, and accomplish reasonable development in the present unique market climate.

FAQs

1. What are some common industrial robotics applications?

Industries like automotive, electronics, food and beverage, and pharmaceuticals employ industrial robots for various tasks such as welding, painting, palletizing, picking and placing items, and tending machines.

2. How do industrial robotics improve productivity and efficiency?

Industrial robotics can work consistently without breaks, prompting expanded efficiency and proficiency. They likewise perform assignments with high accuracy and exactness, limiting mistakes and decreasing creation process durations.

3. What factors should companies consider when implementing industrial robotics?

Organizations ought to consider factors like expense, profit from the venture in industrial robotics, coordination with existing frameworks, well-being prerequisites, and labor force preparation while executing industrial robotics.

4. What role will collaborative robotics play in the future of industrial automation?

Industrial settings are expected to increasingly adopt collaborative robotics, where humans and robots work together in shared spaces. These robots can enhance flexibility, safety, and efficiency in assembly environments.

5. How can companies stay updated on the latest industrial robotics trends and technologies?

Organizations can remain refreshed by going to industry gatherings, partaking in career expos, organizing with advanced mechanics specialists, and drawing in advanced mechanics producers and providers. Furthermore, buying into industry distributions and online gatherings can give significant insights into emerging patterns and advancements.